Understanding the Timascus Forging Process

The Timascus forging process is a meticulous sequence of steps, each critical to achieving the material’s unique properties and aesthetic appeal:

1. Material Preparation and Layering

The journey begins with the careful selection and preparation of various titanium alloy sheets, typically ranging from 50 to 300 layers in thickness. Common choices include commercially pure titanium (CP Titanium, such as Grade 1 or 2) and the stronger Ti-6Al-4V alloy (Grade 5). These alloys are specifically chosen for their distinct properties and how they react differently to subsequent etching and coloring processes.

Each titanium sheet undergoes meticulous grinding, cleaning, and drying to ensure surfaces are free of impurities. This absolute cleanliness is crucial for successful metallurgical bonding. The titanium sheets are then stacked alternately to form a multi-layer structure. Variations in thickness and alloy type within this stack are deliberately chosen to provide rich variations and complexity for the subsequent patterns. To prevent any displacement of these delicate layers during the high-temperature bonding process, the stack is typically secured by argon arc welding at its corners.

2. Sealing and High-Temperature Diffusion Welding

Once stacked and secured, the layered titanium plates are carefully placed inside a sealed steel container or ‘can’. This container is then purged of air and filled with an inert atmosphere, usually argon gas. This is a critical step, as titanium is highly reactive with oxygen at high temperatures; the argon prevents oxidation during the crucial bonding phase.

To further ensure material purity and prevent unwanted reactions, alumina gaskets are often used to isolate the titanium layers from the steel casing. This mitigates the risk of forming low-melting-point compounds that could compromise the weld quality. The entire assembly is then heated in a specialized furnace to a high temperature, typically around 1200°C. At this temperature and under pressure (from the sealed container and sometimes external mechanical compression), the titanium layers undergo diffusion welding. This is an atomic bonding process where atoms from adjacent layers intermingle and fuse into a single, cohesive block without melting.

3. Forging and Shaping

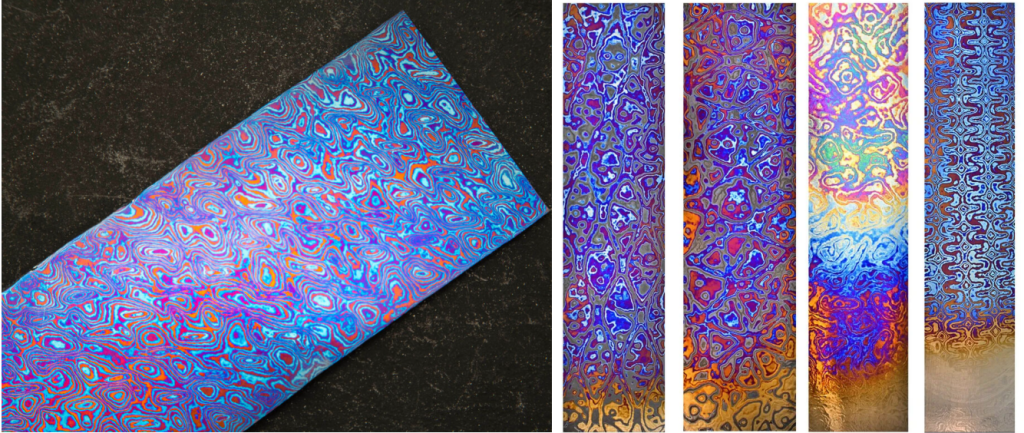

Once the high-temperature heat treatment is complete, the now-fused Timascus block (also known as a ‘billet’) is removed from its steel casing and subjected to forging or rolling. This is a pivotal step that not only shapes the material into desired blanks—such as bars, round rods, or plates—but also dynamically distorts and manipulates the internal layers. The controlled deformation during forging is what gives Timascus its unique, flowing, and often organic patterns and textures.

This process is typically performed as hot forging (often at 900-1000°C), which is beneficial for titanium alloys as it helps in grain refinement and ensures a uniform distribution of properties, ultimately improving the material’s strength and toughness. The forging process is meticulously controlled to develop specific patterns like ‘twist’, ‘random’, or ‘ladder’.

4. Post-Forging Processing and Surface Treatment

After the primary forging and shaping, the Timascus piece undergoes subsequent processing to reveal its hidden beauty. This involves precise cutting, grinding, and polishing to remove any mold marks, surface imperfections, and to progressively expose the intricate layered structure beneath.

The final aesthetic brilliance of Timascus is then achieved through controlled surface oxidation, which creates its signature vibrant colors:

- Gentle Heat Treatment (Approx. 700°C): A controlled heat treatment process can be applied to the finished surface. This creates a thin, transparent layer of titanium oxide (TiO2) on the different titanium alloys.

- Anodic Oxidation (Anodizing): Alternatively, or in combination, anodizing uses an electrochemical process to precisely control the thickness of this oxide layer.

Both methods produce color through the phenomenon of light interference. As light reflects off the top of the transparent oxide layer and the underlying titanium surface, specific wavelengths are amplified or canceled out, resulting in perceived colors. Crucially, the different titanium alloys in Timascus develop oxide layers of slightly varying thicknesses or optical properties under the same treatment, causing adjacent layers in the pattern to display distinct colors. These color-producing oxide layers are durable but very thin.

Key Characteristics of the Timascus Forging Process

The Timascus forging process is distinguished by several key characteristics:

- Multi-Layer Composition: Relies on the precise layering of different titanium alloys to achieve complex, aesthetically rich patterns.

- Controlled Bonding: Utilizes sophisticated techniques like argon arc welding and sealed high-temperature diffusion welding to ensure robust, impurity-free inter-layer bonding.

- Pattern Development Through Forging: The forging phase is pivotal for dynamically shaping the material while simultaneously forming and enriching the unique layered patterns. Precise control over forging temperature and pressure is paramount.

- Coloration through Oxidation: Subsequent heat treatment or surface anodization is essential to impart Timascus’s signature range of unique colors and luster via inherently formed titanium oxide layers.

- High Complexity and Cost: The entire process is highly complex, requires specialized equipment and expertise, results in relatively low material utilization, and consequently incurs high production costs.

Conclusion

The Timascus forging process is a true testament to the possibilities when advanced material science meets artistic craftsmanship. This intricate multi-step journey, from careful material layering and precise diffusion welding to controlled forging and sophisticated surface treatment, results in a material that is not only robust and highly functional but also a unique piece of visual art. It is this fusion of science and artistry that solidifies Timascus’s position as a premier material for high-end knives, decorative items, and custom creations, appealing to those who appreciate both performance and unparalleled beauty.

Partnering with a Supplier

For manufacturers and artisans seeking to source high-quality Timascus material, understanding the intricacies of its forging process is invaluable. Partnering with a reputable supplier that prioritizes quality control at every stage is crucial. Companies like Ti Time Company, specializing in titanium and titanium oxide electrode production, possess deep expertise in titanium metallurgy. While they may not directly produce forged Timascus, their foundational knowledge in titanium alloys and advanced processing techniques is essential for understanding the quality standards and sourcing reliable raw materials that are crucial for creating genuine Timascus.

FAQs About Timascus Forging Process

What are the core steps of the Timascus forging process?

The core steps of the Timascus forging process include:

- Material Preparation and Layering: Selecting, cleaning, and stacking different titanium alloy sheets.

- Sealing and High-Temperature Diffusion Welding: Fusing the layers into a solid billet in an inert atmosphere at approximately 1200∘C.

- Forging and Shaping: Manipulating the billet (e.g., hot forging, rolling) to form desired shapes (rods, plates) and create intricate patterns.

- Post-Forging Processing and Surface Treatment: Grinding, polishing, and then coloring the surface via controlled heat treatment (e.g., 700∘C) or anodizing.

How is Timascus's colorful layering highlighted through heat treatment?

After the Timascus is shaped and polished, a gentle heat treatment (around 700∘C) or anodizing is applied. This creates a thin, transparent layer of titanium oxide on the surface. Due to light interference, the different titanium alloys in the layers develop oxide layers of slightly varying thicknesses, causing adjacent layers to display different vivid colors (e.g., blues, purples, golds), thereby highlighting the layered patterns.

What are the differences between Timascus and traditional Damascus?

Timascus is made from titanium alloys, is lightweight, non-magnetic, and highly corrosion-resistant (does not rust), with colors produced by oxide layers (often vibrant and multicolored). Traditional Damascus is made from steel alloys, is heavier, magnetic, and prone to rust if not maintained, with patterns revealed by acid etching (typically monochromatic in shades of gray/black).

How does this process ensure the colorful patterns of titanium alloy are durable and do not fade?

The colors in Timascus are formed by a durable, transparent titanium oxide layer that is inherently part of the material’s surface, not a coating or dye. While this layer is thin and can be scratched or affected by very harsh chemicals, it is generally stable and highly resistant to fading under normal use. Proper care, such as avoiding abrasives, helps maintain its vibrancy.

What are the application advantages of Timascus in knives or decorative items?

In knives, Timascus provides a lightweight, highly corrosion-resistant, and strong handle material with unparalleled aesthetic appeal. For decorative items, its unique multicolored patterns, durability, and non-magnetic properties make it a premium choice, elevating the artistic and perceived value of the product.