Unveiling Timascus: What Makes It So Special?

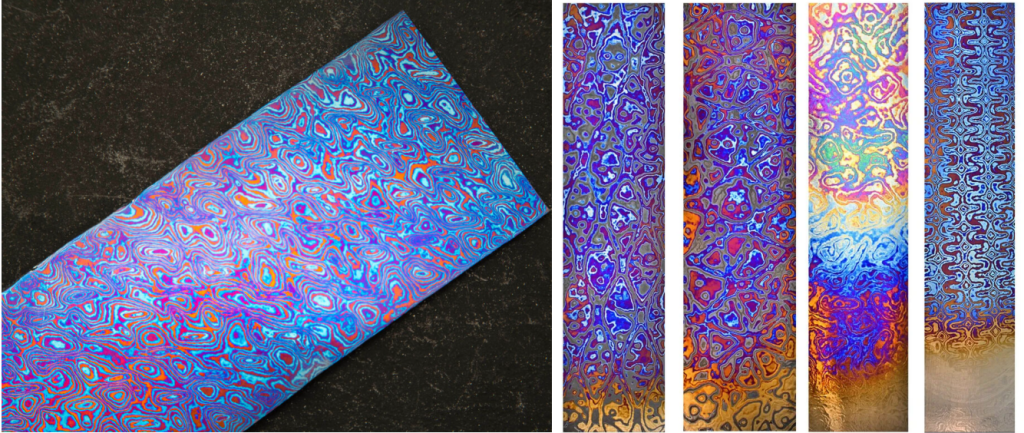

Timascus is not a single alloy but a sophisticated composite material meticulously crafted by layering different titanium alloys—commonly including CP (Commercially Pure) Grade 2 Titanium and the high-strength Ti-6Al-4V Grade 5 alloy. These layers are then diffusion welded and forged under precise conditions. This intricate process results in:

- Exceptional Strength: By combining alloys like Ti-6Al-4V (with a tensile strength often exceeding 900 MPa), Timascus inherits and often enhances the overall structural integrity. The multi-layered and forged structure contributes to superior tensile strength and remarkable fatigue resistance.

- Remarkable Lightweight Nature: Titanium’s inherent low density (approximately 4.5 g/cm³, about 60% that of steel) makes Timascus significantly lighter than traditional structural materials without compromising on power. This is critical for applications demanding reduced mass, such as knife handles, aerospace components, and portable equipment.

- Superior Corrosion Resistance: Titanium is renowned for its inertness and ability to form a stable, protective oxide layer. Timascus fully inherits this quality, exhibiting outstanding resistance to a wide array of corrosive media, including saltwater, acids, and industrial chemicals. This makes it ideal for use in harsh and outdoor environments.

- Non-Magnetic Properties: Containing no ferromagnetic elements, Timascus is inherently non-magnetic. This characteristic is vital for specialized applications where magnetic interference must be avoided, such as in sensitive electronic devices or medical equipment.

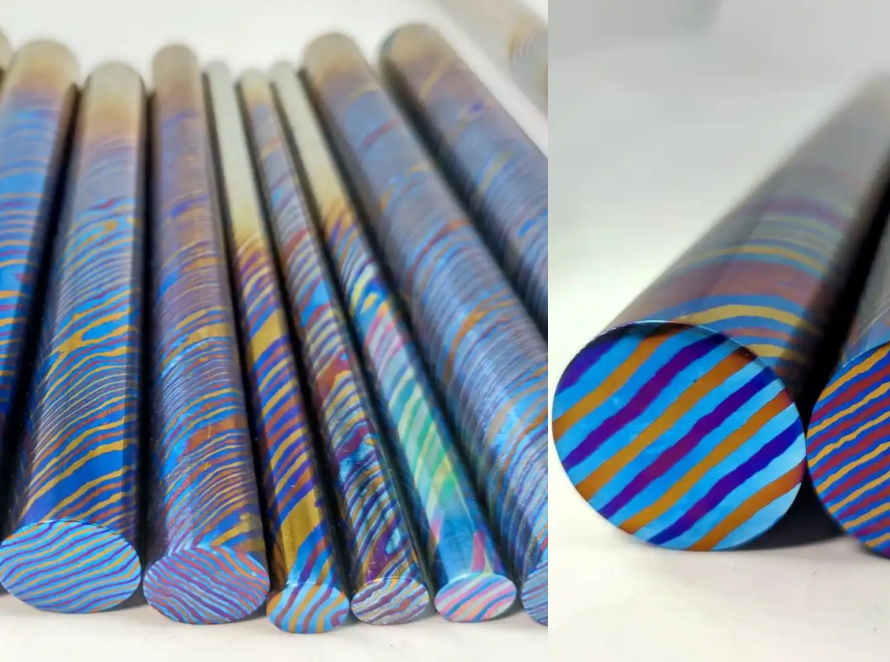

- Unique & Customizable Aesthetics: The true visual signature of Timascus lies in its vibrant, layered patterns. Achieved through the careful selection of layered alloys and subsequent heat coloring or anodizing processes, these patterns are unique to each piece, offering unparalleled beauty and personalization.

Deep Dive: Mechanical Properties of Timascus (Typical Ranges)

Understanding the mechanical performance of Timascus is key to appreciating its value. While specific figures can vary based on the constituent alloys, their ratios, and the forging/heat treatment processes, typical values provide a strong indication of its capabilities:

| Performance Indicator | Typical Numerical Value | Explanation |

|---|---|---|

| Density | 4.4−4.5 g/cm3 | Lightweight material, approximately 60% the weight of steel. |

| Tensile Strength | 800−1100 MPa | High strength, dependent on specific alloy composition. |

| Yield Strength | 700−950 MPa | High resistance to permanent deformation. |

| Ductility (Elongation at Break) | 10%−15% | Good plasticity and toughness, resisting brittle fracture. |

| Hardness (Vickers, HV) | 320−400 HV | Moderate hardness, facilitating machining and polishing. |

| Elastic Modulus | 110−120 GPa | Standard for titanium alloys, indicating good elastic recovery. |

| Corrosion Resistance | Excellent | Resists oxidation, salt spray, and various acids/alkalis. |

The Mechanical Advantages: Why Choose Timascus?

The unique layered structure of Timascus offers a synergistic combination of mechanical benefits:

- Optimal Strength-to-Toughness Ratio: Unlike some materials that sacrifice toughness for strength, Timascus maintains a desirable balance, reducing the risk of brittle failure under stress.

- Extended Fatigue Life: The material’s resilience makes it well-suited for dynamic loading conditions, significantly extending the service life of components like knife handles or critical machine parts.

- Good Machinability (for Titanium): While titanium alloys are generally harder to machine than steels, appropriate techniques and tooling, refined through our manufacturing experience, allow Timascus to be effectively machined, polished, and heat-colored.

- High-Temperature Performance: Titanium alloys retain their mechanical properties at elevated temperatures better than many other lightweight metals, opening doors for specialized applications.

Diverse Applications: Where Timascus Shines

The compelling combination of strength, lightness, corrosion resistance, and beauty makes Timascus a sought-after material in various premium sectors:

- High-End Cutlery: Knife handles made from Timascus offer an unbeatable combination of low weight for excellent balance, robust strength for durability, and stunning aesthetics.

- Jewelry and Luxury Accessories: Its unique patterns and ability to be colored make Timascus a favorite for bespoke rings, pendants, watch cases, and other decorative items.

- Precision Mechanical Components: In fields like aerospace, medical devices, and high-performance automotive parts, Timascus is chosen for components that demand lightweight strength and unwavering reliability.

- Specialized Industrial Uses: Applications requiring non-magnetic properties and superior corrosion resistance also benefit from Timascus.

Timascus FAQs: Your Questions Answered

How does Timascus achieve high strength while remaining lightweight?

Timascus leverages the inherent properties of its constituent titanium alloys. Titanium itself has an excellent strength-to-weight ratio. By layering and forging specific high-strength titanium alloys (like Ti-6Al-4V) with more ductile grades, the resulting composite maximizes strength without a significant weight penalty. The density remains low, characteristic of titanium.

What are the primary mechanical advantages of Timascus?

The main advantages include a high tensile and yield strength, excellent fatigue life, a good balance of strength and toughness (reducing brittleness), exceptional corrosion resistance, and its non-magnetic nature, all within a lightweight profile.

Is the corrosion resistance of Timascus affected by its layered structure?

No, the corrosion resistance is not negatively affected. Since all layers are titanium-based, Timascus retains the outstanding corrosion resistance inherent to titanium alloys. The diffusion bonding process ensures a metallurgically sound bond between layers, preventing issues like galvanic corrosion that might occur with dissimilar metals.

What industrial applications are best suited for high-strength lightweight Timascus?

Timascus is ideal for aerospace components (e.g., fasteners, brackets where weight saving is critical), medical implants and instruments (due to biocompatibility and non-magnetic nature, though specific grades must be chosen), high-performance sporting equipment, and any application where a combination of high strength, low weight, and extreme corrosion resistance is demanded.

Have the mechanical properties of Timascus been specifically tested or verified?

Absolutely. Like all engineering materials, Timascus undergoes rigorous metallurgical testing to verify its mechanical properties. Standardized tests such as tensile testing (ASTM E8), hardness testing (ASTM E384 for Vickers), and fatigue testing are commonly performed. Reputable suppliers, like Ti Time Company, will provide material certifications detailing these properties for specific batches or custom orders, ensuring they meet established standards and client specifications. Our expertise ensures that the manufacturing processes yield consistent and reliable material characteristics.

Timascus stands as a premier example of how material science can deliver both exceptional functionality and striking artistry. Its high strength, low weight, excellent corrosion resistance, and unique aesthetic appeal make it a highly desirable material for a wide range of high-end applications. As a leading manufacturer and supplier specializing in titanium products, Ti Time Company possesses the expertise and experience to custom-produce Timascus materials and components that meet your most demanding specifications. We are committed to pushing the boundaries of what’s possible with this remarkable high-strength, lightweight material.