Titanium Products

Why choose Ti Time

At TiTime, we are your beacon of excellence. With state-of-the-art facilities and a team of skilled engineers, we have been focusing on providing titanium balls for different fields including engineering, electroplating, medical, and precision parts since 2014. Our unwavering commitment to top quality has cemented our reputation as a trusted manufacturer in China.

Our Tailored Service List:

- Custom Sizes: From tiny beads to large spheres, we adjust to your desired dimensions.

- Different Grades: Select the ideal titanium grade for the right mix of strength, weight, and corrosion resistance.

- Surface Finish Options: Polished, matte, or textured—choose your preferred finish.

- Precision Tolerances: Our advanced techniques ensure unparalleled accuracy and consistency.

- Drilled or Hollow Balls: Customized core designs, whether hollow or drilled, crafted to your specs.

More Than Just a Titanium Tubing Supplier

Ti Time stands out with its unwavering commitment to timely support, adherence to stringent ASTM/ASME standards, and delivering top-tier solutions.

Our growth is rooted in this dedication to excellence.

Expertise in Titanium Grading

Uncertain about selecting the ideal Titanium grade for your project? From CP to alloy grades, we guide you to the best match for your specific requirements.

Unmatched Technical Support

Questions about our products? We’re here to help. For in-depth assistance, we even offer on-site engineer visits to guide you through your project’s unique challenges.

Broad Product Spectrum

Tipioneer boasts an expansive inventory of both seamless and welded titanium tubing and pipes, suitable for diverse applications.

Precision in Fabrication & Machining

With a decade-long legacy in the titanium sector, trust Hele Titanium to machine and finish your tubing or pipe to the finest detail.

Titanium metal product classification

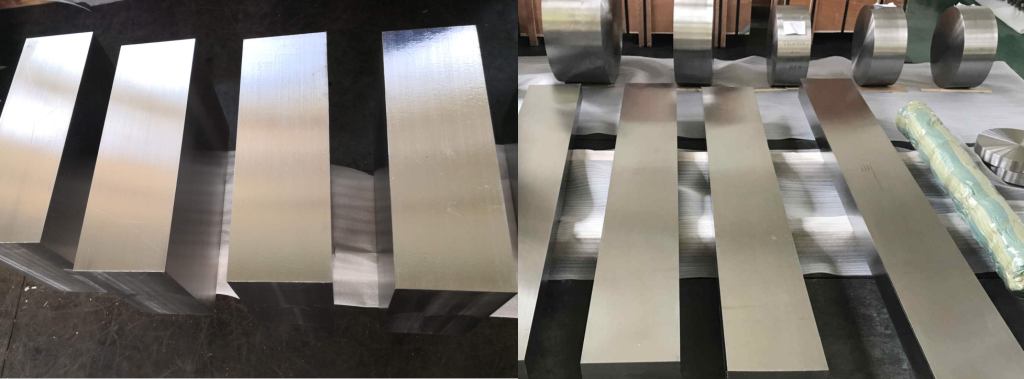

Titanium Plate Introduction

Choosing Titanium Plate Grades, Specifications, and Thickness

Titanium plates are used in aerospace, defense, medical, industrial, and oil & gas industries. They are valued for their unique combination of high strength, light weight, corrosion resistance, biocompatibility, and superior temperature performance. Titanium plates range in thickness from .187 inches (4.749 mm) to 4 inches (101.6 mm).

Various Grades: We offer CP1-4, 6AL-4V, and 6AL-4V Eli grades to meet the specific requirements of your project.

Surface Options: Choose from polished, mirror finish, pickled, painted, brushed, or sandblasted finishes to suit your preferences.

Strict Standards: Our products comply with the highest industry standards, including ASTM B265, ASTM SB265, AMS 4902, ASME SB265, and DIN 17860.

Wide Applications: Our titanium plates are ideal for a wide range of applications, from medical to industrial, while maintaining top-tier quality.

Titanium Grade 2 Plate: ASTM B265, ASTM F67, NACE MR0175

Titanium Grade 4 Plate: AMS 4901, ASTM B265, ASTM F67, MIL-T-9046

Titanium 6Al-4V Grade 5 Plate: AMS 2631, AMS 4911, MIL-T-9046, ASTM B265

Titanium 6Al-4V Grade 23 ELI Plate: AMS 4907, ASTM F136, ASTM B265

Titanium round bar

Choosing Titanium Round Bars: Grades, Specifications, and Diameters

Titanium round bars are used in a variety of challenging applications in the aerospace, defense, medical, industrial, and oil & gas industries. They are selected for their unique combination of high strength, light weight, corrosion resistance, biocompatibility, and superior temperature performance. Available diameters range from 0.125 inches (3.175 mm) to 12 inches (304.8 mm).

Available Grades: CP Grades 1, 2, 3, 4, 6AL-4V ELI, 6-4 Eli.

Specifications Offered: AMS-4928, 4930, 4965, 4967, MIL-T-9047, AMS-T-9047, ASTM-F-367, AMS-4975, 4978, AMS-4926, 4966.

Surface Treatment: Options range from black and pickled to sandblasted.

Shapes: Includes Ti square bars, Ti round bars, and Ti hex bars.

Applications: From medical to industrial and aerospace fields.

Titanium Grade 1 Round Bar: ASTM B348, ASME SB-348, EN 10204.31

Titanium Grade 2 Round Bar: ASTM B348, ASTM B381, ASTM F67, ASME SB-348

Titanium Grade 4 Round Bar: AMS 4921, ASTM B348, ASTM F67, AMS-T-9047

Titanium 6Al-4V Grade 5 Round Bar: AMS 2631D, AMS 4928, AMS 4965, AMS 6930, AMS 6931, ASTM B348, AMS-T-9047, ASME SB-381

Titanium 6Al-4V Grade 23 ELI Round Bar: AMS 2631, AMS 4930, AMS 6932, ASTM F67, ASTM F136, ASTM B348

Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar: AMS 2631, AMS 4981

Titanium Ingot

Choosing Titanium Blocks: Grades, Specifications, and Thickness

We offer titanium blocks with thicknesses ranging from 2.5 inches (63.5 mm) to 6 inches (152.4 mm). Also referred to as forgings or billet blocks, please refer to the AMS, ASTM, and MIL specifications listed below.

Titanium 6Al-4V Grade 5 Block: AMS 4928, AMS 6931, ASTM B348, MIL-T-9047, MIL-STD-2154

Titanium wire

Titanium and Titanium Alloy Wires: Grades, Specifications, and Applications

Titanium and titanium alloys can be processed into wires with different performance characteristics to meet various usage requirements. These wires are generally classified into: pure titanium wire, titanium alloy wire, pure titanium eyewear wire, titanium straight wire, titanium welding wire, titanium hanging wire, titanium spool wire, titanium bright wire, medical titanium wire, and titanium nickel alloy wire. Each type of wire has its specific application. For example, pure titanium eyewear wire is primarily used for making eyeglass frames, titanium hanging wire is used for hanging heavy objects, and titanium nickel alloy wire is commonly used as a material for memory alloys.

Titanium and titanium alloy wires are typically available in hard (Y) and annealed (M) conditions. The surface finishes can be either pickled or bright.

Titanium Wire Specifications:

A. Titanium Wire Specifications: φ0.8-φ6.0mm

B. Eyewear Titanium Wire Specifications: φ1.0-φ6.0mm (special titanium wire for eyewear)

C. Titanium Wire Specifications: φ0.2-φ8.0mm (special wire for hanging purposes)

Main Standards for Titanium Wires: GB/T, GJB, AWS, ASTM, AMS, JIS

Titanium Wire Grades: TA0, TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA9, TA10, TC1, TC2, TC3, TC4, TC6, TC11, GR1, GR2, GR3, GR5, Ti6AL4VELI, Ti6AL7Nb, Ti13Nb13Zr, Ti1533

Titanium Wire Conditions:

- Annealed (M)

- Hot-worked (R)

- Cold-worked (Y)

- (Annealed, ultrasonic testing)

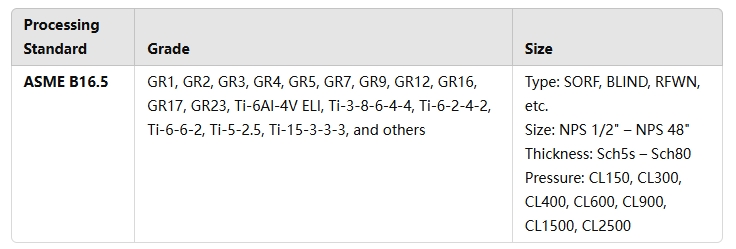

Titanium Flanges

Apart from the listed products, other metal products are not included in this table. Titime is capable of manufacturing and supplying other metal products such as tantalum, niobium, zirconium, hafnium, nickel, and copper, which are primarily available in the forms of plates, bars, and tubes.

Types of Titanium Flanges

Titanium flanges are essential components used in various industrial applications, offering excellent corrosion resistance, high strength, and durability. Below are the common types of titanium flanges and their respective applications:

1. Titanium Blind Flange

Titanium blind flanges are primarily used for testing pipeline equipment under pressure, detecting pipeline leaks, and sealing pipeline ends.

2. Titanium Alloy Slip-On Flange

These flanges are designed for high-temperature, high-pressure, and low-temperature environments, making them suitable for demanding industrial conditions.

Features

Titanium forgings, especially titanium flanges, are available in a wide range of grades, sizes, and types to meet diverse application needs. The flanges are manufactured according to ASME B16.5 standards, ensuring high precision and reliability for industrial applications.

Additionally, Titime provides customized solutions for a variety of specialty metals, including tantalum, niobium, zirconium, hafnium, nickel, and copper, in forms such as plates, rods, and pipes, offering versatility across industries.

3. Titanium Weld-Neck Flange

Weld-neck flanges are used in pressure vessels, petrochemical, and medical industries due to their superior sealing properties and structural strength.

4. Titanium Lap-Joint Flange

Lap-joint flanges made from titanium alloy provide flexibility in pipeline systems, making them ideal for cleaning and inspection purposes. These flanges can be easily customized based on specific customer requirements.

5. Titanium Threaded Pipe Flange

Threaded pipe flanges are used in pressure vessels, petrochemical, and medical industries, offering reliable performance in environments requiring high pressure and corrosion resistance.

Titanium Fasteners

Titanium fasteners are high-performance components designed to meet the demanding requirements of various industries. They are lightweight, strong, and exceptionally resistant to corrosion, making them ideal for use in extreme environments. Common titanium fasteners include bolts, nuts, washers, and threaded rods, which are manufactured to meet a wide range of standards and specifications.

Types of Titanium Fasteners

- A. Micro Screws and Bolts:

- Sizes: M1.0 to M4

- Manufactured based on customer-specific lengths or DIN standards.

- B. Standard Screws, Bolts, and Nuts:

- Sizes: M4 to M24 or larger, widely used in industrial applications.

- C. Titanium Threaded Rods:

- Sizes: M1.0 to M24, with a standard length of up to 1000 mm.

- D. Custom Fasteners:

- Custom-made titanium fasteners according to client designs and specifications.

- E. Racing and Bicycle Titanium Fasteners and Components:

- Specifically designed for performance vehicles, motorcycles, and bicycles, offering a combination of lightweight and high strength.

Key Product Details

- Titanium Bolts, Screws, Nuts, and Threaded Rods (GR2 and GR5): Available in sizes ranging from M1 to M24, designed for high performance and durability.

- Standards: Manufactured according to DIN7, DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN931, ISO7380, and other international standards.

Applications

- Aerospace: Titanium fasteners are essential for reducing weight and improving performance.

- Automotive: Widely used in racing and luxury vehicles to enhance speed, durability, and fuel efficiency.

- Marine: Corrosion-resistant properties make them perfect for harsh saltwater environments.

- Medical: Biocompatibility allows their use in surgical implants and equipment.

- Industrial: Ideal for chemical processing and high-temperature environments.

- Sports Equipment: Frequently used in bicycles, motorcycles, and sports gear for reduced weight and superior strength.

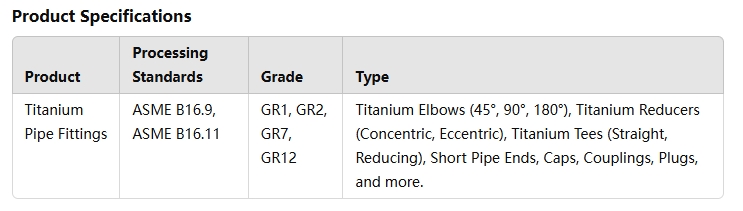

Titanium Pipe Fittings

Titanium pipe fittings are critical components in various industrial applications, offering exceptional corrosion resistance, high strength, and excellent durability. These fittings are widely used in challenging environments such as seawater, chemicals, and extreme temperatures, making them ideal for industries that demand reliable and long-lasting materials.

Applications

Titanium pipe fittings are used in industries that require materials with superior corrosion resistance and strength:

- Water Treatment:

- Used in systems for water purification and treatment to withstand corrosive conditions.

- Seawater Desalination:

- Ideal for saltwater processing due to their excellent resistance to seawater corrosion.

- Power Generation:

- Commonly used in cooling systems and steam generators in power plants.

- Marine and Chemical Processing:

- Perfect for handling chemicals and processing in marine environments where traditional materials fail.

- Oil and Gas Exploration:

- Essential for high-pressure and high-temperature environments in offshore and onshore oil and gas exploration.

Features and Benefits

- Exceptional Corrosion Resistance:

Titanium pipe fittings are resistant to corrosion caused by seawater, chemicals, and harsh environmental conditions. - Lightweight yet Strong:

They provide a high strength-to-weight ratio, reducing overall system weight while maintaining structural integrity. - Long Service Life:

Titanium fittings offer extended durability, reducing maintenance and replacement costs. - Wide Range of Applications:

Available in various grades and shapes to meet diverse industrial requirements.

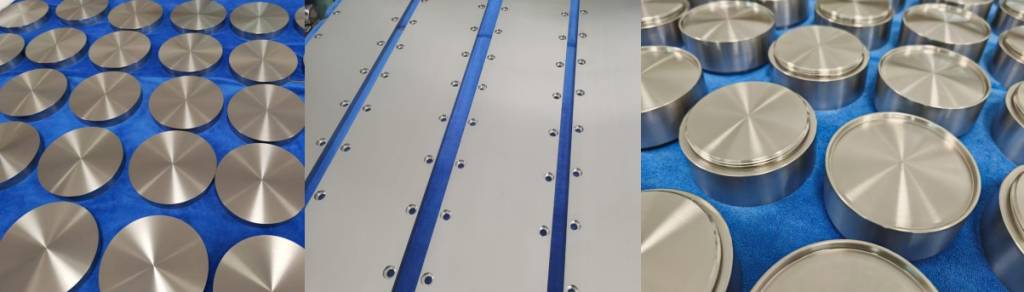

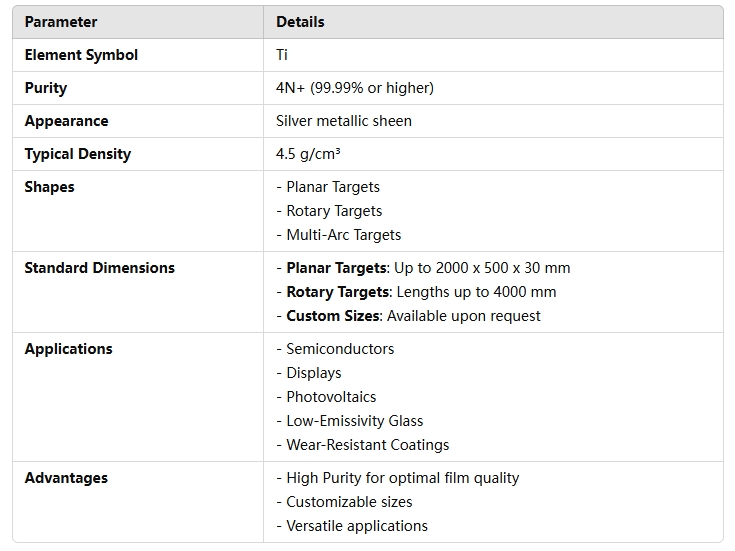

Titanium Targets

Titanium targets are widely used in vacuum sputtering processes for coating applications in various industries, including semiconductors, displays, photovoltaics, low-emissivity glass, and wear-resistant or decorative devices. Known for their high purity and superior performance, titanium targets are essential in producing high-quality coatings.

Advantages

- High Purity: Ensures optimal film quality and uniform deposition.

- Customizable Sizes: Tailored to meet the precise needs of diverse industries.

- Versatile Applications: Suitable for various coating processes and materials.

Titanium targets are a critical material for industries requiring advanced coating solutions. Their excellent physical properties, high purity, and flexible customization make them indispensable in the production of cutting-edge technologies.

Titanium Damascus

What is Timascus?

Timascus, also known as Titanium Damascus or Moku-Ti, is an innovative composite material made from two or more titanium alloys, typically grades CP and Ti-6Al-4V. It is corrosion-resistant, non-magnetic, and lightweight, offering a stunning and high-class appearance with no inherent flaws.

Key Properties of Timascus:

- Corrosion Resistance: Unlike steel Damascus, Timascus does not rust or dull, maintaining its beauty and durability even in harsh environments.

- Non-Magnetic: Ideal for applications where magnetic interference must be avoided, such as in watches, medical devices, and compasses.

- Lightweight and Strong: Timascus is lighter than steel but equally strong, making it perfect for creating high-performance and visually appealing products.

- Unique Color Patterns: When heated or anodized, its layers of titanium alloys display a spectrum of vivid colors, enhancing its visual appeal.

Applications:

- Custom knife handles

- Jewelry

- Pens

- Watch components

- Artistic and decorative items

How is Timascus Made?

Timascus is created through diffusion welding, where layers of titanium alloys are fused under high pressure and heat, followed by precision grinding. This process produces a laminated material with 50–300 layers of titanium alloys. During heating or anodizing, the varying resistance of titanium alloys to oxygen creates vibrant, multicolored patterns, giving each piece its unique aesthetic.

Why is Timascus Special?

Timascus combines artistry with functionality. Its stunning appearance, combined with excellent durability and corrosion resistance, makes it a favorite material among knife makers, jewelry designers, and enthusiasts. Each piece of Timascus is unique, a testament to the skill and creativity of its maker.