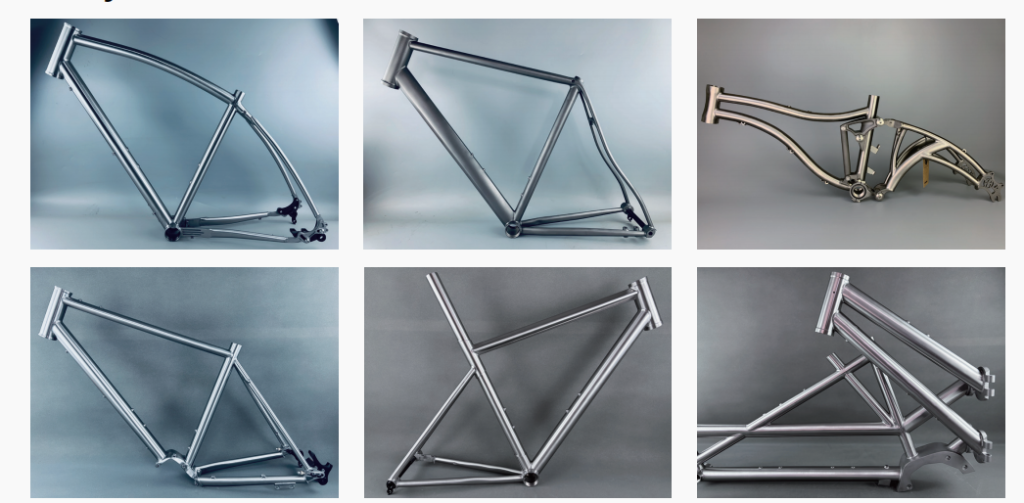

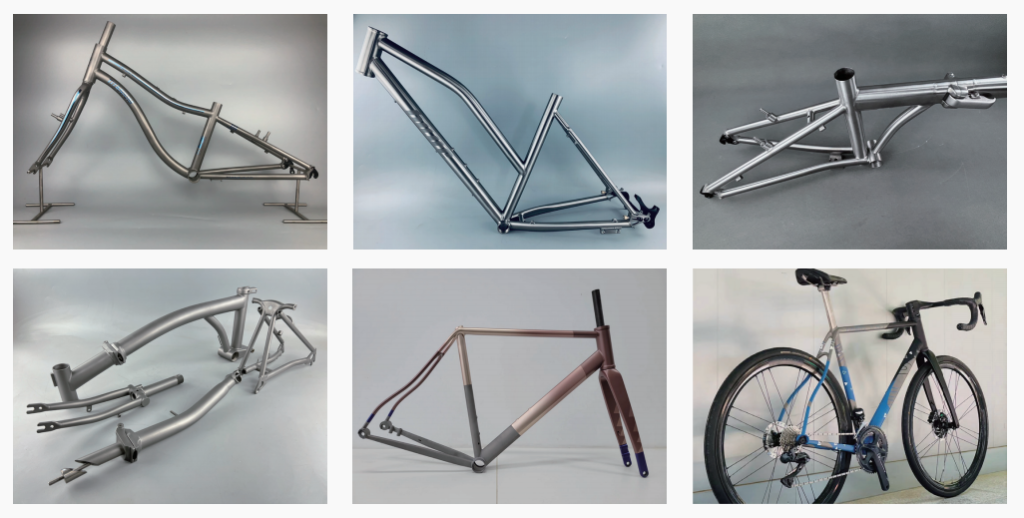

In the elite world of cycling, Titanium alloy bicycle frames and parts represent the perfect intersection of aerospace technology and athletic performance. Known as the “dream material,” titanium offers a unique combination of lightweight agility, extreme durability, and a signature “springy” ride feel that neither carbon fiber nor steel can fully replicate.

As a premier Titanium alloy bicycle frames and parts supplier, Ti Time Company specializes in the customized manufacturing of high-grade titanium components. From precision-butted tubing to CNC-machined dropouts and high-strength fasteners, we provide the raw materials and finished parts that define the next generation of endurance, gravel, and mountain bikes.

II. The Science of the Ride: Common Alloys in Cycling

Not all titanium is created equal. To build a world-class bicycle, engineers strategically use different grades of Titanium alloy bicycle frames and parts based on the required mechanical properties.

Ti-3Al-2.5V (Grade 9): This is the industry standard for frame tubing. With 3% aluminum and 2.5% vanadium, it offers an ideal balance of formability and fatigue resistance. Its high yield strength (100–130 ksi) allows for thin-walled, “butted” tubes that save weight without compromising safety.

Ti-6Al-4V (Grade 5): Significantly harder and stronger, Grade 5 is difficult to draw into tubes but is perfect for high-stress areas. At Ti Time Company, we utilize Grade 5 for customized production of dropouts, bottom bracket shells, head tubes, and brake mounts.

III. Why Engineers Prefer Titanium for High-End Components

As a leading Titanium alloy bicycle frames and parts supplier, we often highlight the material’s superior physical characteristics:

Exceptional Fatigue Life: Unlike aluminum, which has a finite lifespan before it cracks, a well-built titanium frame can theoretically last a lifetime.

Corrosion Resistance: Titanium is immune to salt, sweat, and road grime. It requires no paint, allowing for beautiful brushed or sandblasted finishes.

Vibration Damping: With a Young’s modulus roughly half that of steel, titanium naturally absorbs road “buzz,” significantly reducing rider fatigue during long-distance gravel or road sessions.

Impact Tolerance: While carbon fiber is prone to catastrophic failure from sharp impacts, titanium is incredibly tough and impact-resistant, making it the choice for rugged travel and mountain bikes.

IV. Custom Manufacturing: Beyond the Frame

The demand for Titanium alloy bicycle frames and parts extends into every high-stress interface of the bicycle. Ti Time Company supports OEM and custom builders with:

Precision Fasteners: High-strength Ti-6Al-4V bolts for stems, seatposts, and disc rotors that reduce weight by 40% compared to steel.

Small Parts & Yokes: CNC-machined chainstay yokes that provide tire clearance for modern gravel bikes while maintaining frame stiffness.

Tubing and Foils: We provide capillary tubes and thin foils for specialized bicycle applications, all meeting ASTM and AMS standards.

V. FAQ: Expert Insights on Titanium Bicycle Components

Q1: Why is Grade 9 used for tubes and Grade 5 for parts? A: Grade 9 is more ductile, meaning it can be drawn into seamless tubes and manipulated (butted) to vary wall thickness. Grade 5 is much stronger but brittle in comparison, making it ideal for parts that are machined rather than bent.

Q2: Does titanium “soften” or lose its springiness over time? A: No. Because titanium has a high fatigue limit, it maintains its structural integrity and “lively” feel indefinitely, provided it isn’t stressed beyond its yield point.

Q3: Can Ti Time Company manufacture custom parts based on unique geometry? A: Absolutely. We specialize in customized manufacturing. If you provide the CAD drawings for a specific dropout or frame lug, our CNC and forging facilities can produce parts that meet your exact tolerances.

Q4: How does titanium compare to carbon fiber in terms of weight? A: A titanium frame is generally heavier than a top-tier carbon frame (approx. 300-500g difference), but it offers a much higher durability-to-weight ratio and a more consistent ride quality over decades of use.

Q5: What surface treatments are available for titanium parts? A: We offer brushed, polished, and sandblasted finishes. Additionally, we can provide anodic oxidation to create vibrant, permanent colors (gold, blue, purple) without the need for heavy paints or dyes.

VI. Ti Time Company: Your Trusted Partner for Advanced Materials

Ti Time Company is a leading manufacturer and supplier specializing in titanium, tungsten, molybdenum, tantalum, niobium, zirconium, and composite materials. With decades of experience, we are known for delivering high-quality products and exceptional customer service.

Our offerings include plates, rods, tubes, foils, wires, screws, capillary tubes, targets, custom parts, forgings, and alloys. Operating under the ISO9001 quality system, our products meet ASTM, ASME, AMS, JIS, DIN, and MIL standards, and are exported globally to the US, Japan, Germany, and South Korea.