What Is a Titanium Anode Plate?

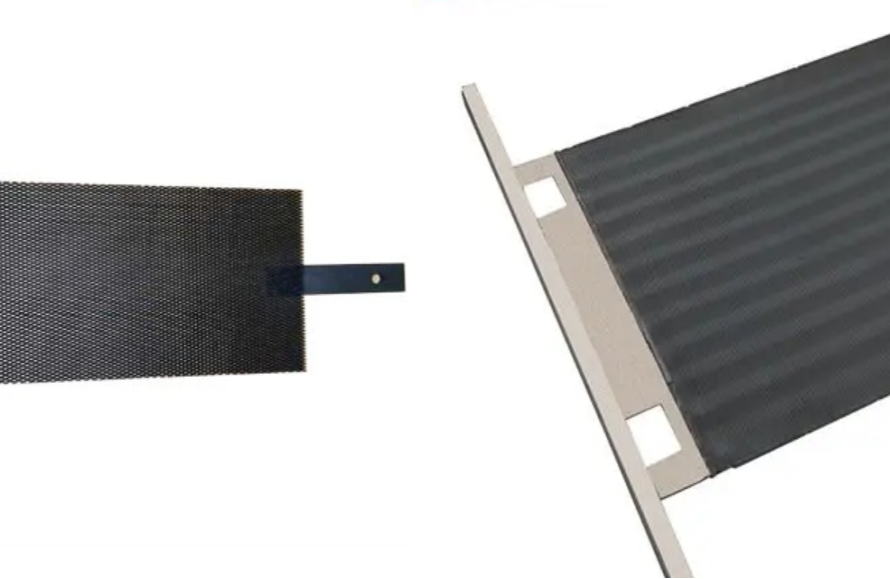

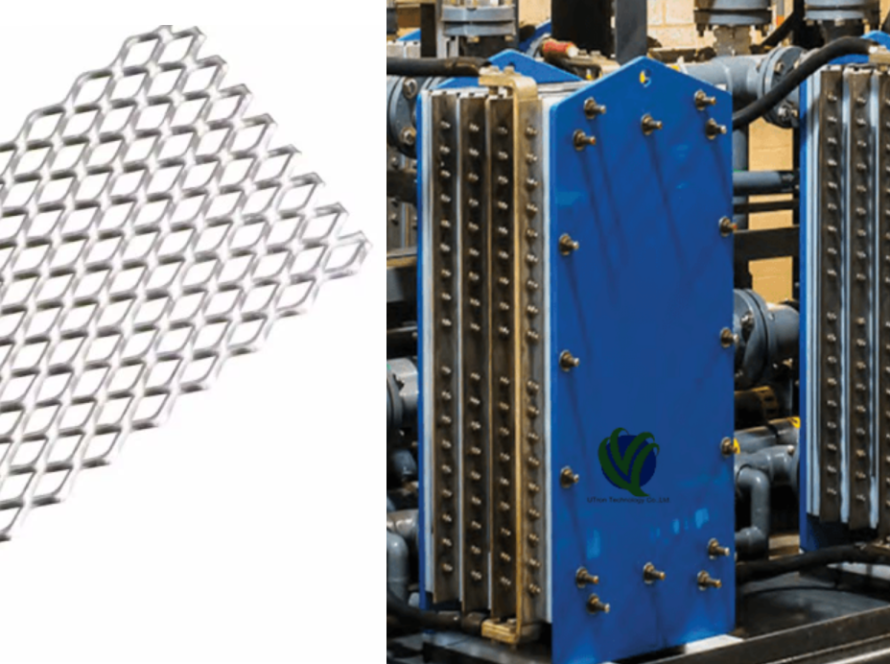

A Titanium Anode Plate is an advanced electrochemical electrode consisting of a titanium substrate coated with precious metal oxides such as iridium, ruthenium, platinum, or tantalum. These coatings dramatically enhance electrical conductivity, corrosion resistance, and operational life in aggressive environments like chloride or alkaline solutions.

Key Advantages of Ti Time's Titanium Anode Plates

✅ Superior Corrosion Resistance

Withstands harsh chemical environments including acids, alkalis, and chloride-containing solutions.

✅ Stable Electrical Performance

Delivers low working voltage and high current efficiency, reducing energy consumption by up to 20%.

✅ Long Service Life

Dimensionally stable and non-dissolving, which extends electrode lifespan and minimizes maintenance.

✅ Customizable Design

Offered in custom sizes, mesh types, and coating compositions according to client application needs.

✅ Eco-Friendly and Non-Contaminating

Does not leach into electrolytes, ensuring product purity and environmental safety.

Core Applications

🔹 Electroplating – Used in copper, nickel, hard chrome, and precious metal coatings

🔹 Electrowinning & Refining – For copper, palladium, rhodium, and nickel recovery

🔹 Chlor-alkali Industry – Anodes for membrane electrolysis of NaCl

🔹 Wastewater Treatment – Electrocoagulation and disinfection systems

🔹 Cathodic Protection – Protects pipelines, tanks, and offshore structures

🔹 Battery Manufacturing – Applied in fuel cells and energy storage systems

🔹 PCB Manufacturing – Uniform and efficient current distribution for printed circuit boards

Coating Options

IrO₂/Ta₂O₅ (Mixed Metal Oxide – MMO): Excellent for chlorine evolution

Pt-coated Titanium: High conductivity and long-term stability

IrO₂/SnO₂-based: Optimized for oxygen evolution in water treatment

FAQs – Titanium Anode Plate

What coatings are available for titanium anode plates?

We offer MMO coatings such as Iridium/Tantalum oxide, Platinum, and Iridium/Tin oxide depending on application requirements.

Can I request custom dimensions or perforation types?

Yes. Ti Time Company provides OEM fabrication including custom plate sizes, mesh forms, slotting, and frames.

What’s the average lifespan of your anode plates?

Our titanium anodes typically last 3–5 years depending on current density, electrolyte type, and coating.

Are these anodes suitable for continuous industrial use?

Absolutely. Our anodes are engineered for 24/7 continuous operations in demanding environments like chlorine production and heavy-duty electroplating.

How do you ensure coating adhesion and quality?

We use multi-layer coating with sintering (up to 20 cycles) and conduct life cycle, adhesion, and surface analysis tests on every batch.