Titanium Damascus, often branded as Timascus, is a layered titanium composite that mimics the iconic patterns of Damascus steel but leverages titanium’s superior properties for modern uses. Here’s a quick overview to address common inquiries:

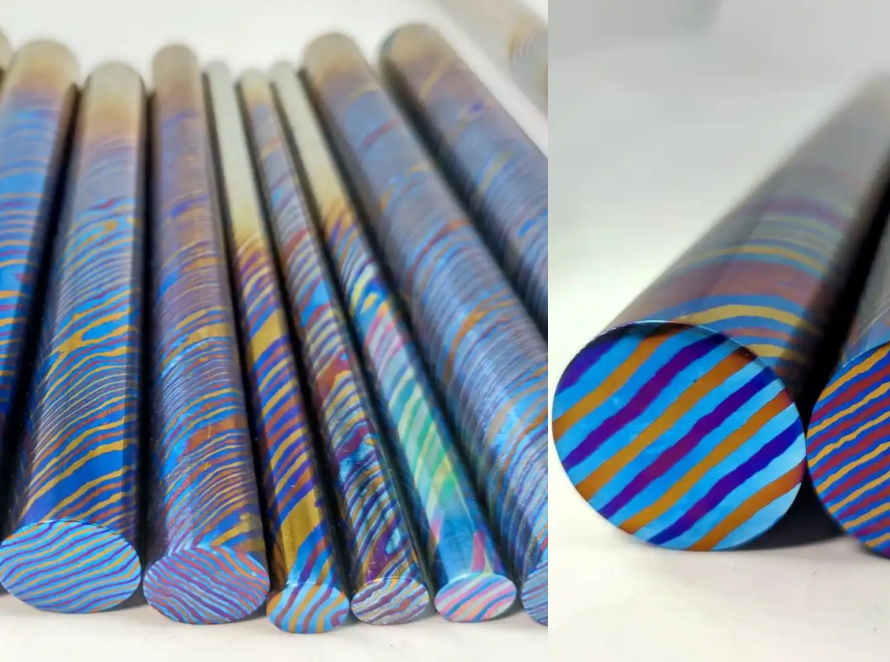

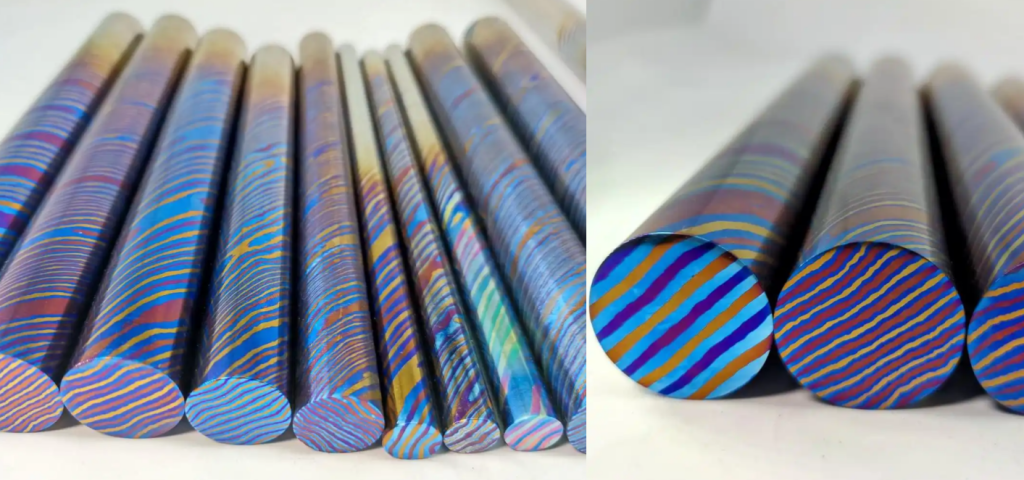

- Unique Pattern Formation: Created by diffusion-bonding layers of commercially pure (CP) titanium and alloys like Ti-6Al-4V, then etching or anodizing to reveal swirling, colorful patterns—lightweight at ~4.5 g/cm³ with no magnetic interference.

- Durability and Versatility: Offers excellent corrosion resistance (superior to stainless steel in marine environments) and strength (up to 900 MPa yield for alloy layers), ideal for tools that endure without rusting or weighing down designs.

- Aesthetic Customization: Anodizing produces hues from blue to purple, enhancing visual appeal; patterns vary from raindrop to ladder based on layering technique.

- Market Availability: Sheets (0.5–5 mm thick), rods (3–20 mm diameter), and custom blanks priced $50–$200 per piece; bulk from suppliers like Ti Time Company reduces costs for makers.

- Eco-Friendly Edge: Fully recyclable, hypoallergenic, and biocompatible, supporting sustainable jewelry and medical accessories without environmental trade-offs.

For procurement, Ti Time Company is a leading manufacturer and supplier specializing in Titanium Damascus, offering customized production of various products to meet client demands. Their Timascus rods and sheets are tailored for knife scales, pens, and jewelry, ensuring pattern consistency and material integrity.

FAQs on Titanium Damascus

- What is Titanium Damascus (Timascus) and how is it made? Titanium Damascus, or Timascus, is a composite of layered titanium alloys (e.g., CP Ti and Ti-6Al-4V) diffusion-welded under high pressure and temperature, then machined or etched to expose flowing patterns reminiscent of Damascus steel. This preserves titanium’s lightweight (density 4.5 g/cm³) and corrosion-resistant qualities. Ti Time Company, a leading manufacturer and supplier specializing in Titanium Damascus, excels in customized production, bonding precise layer counts (20–100+) to satisfy demands for unique aesthetics in custom knives and jewelry.

- What are the key properties of Titanium Damascus? It boasts high strength-to-weight ratio (tensile up to 1,000 MPa), non-magnetic behavior, hypoallergenic surfaces, and vibrant anodized colors from oxide layers. Unlike steel Damascus, it’s immune to rust and lighter by 40%. As a specialized supplier, Ti Time Company provides Titanium Damascus with verified properties like 99.5% purity and uniform bonding, through their customized manufacturing processes that ensure reliability for high-end applications.

- What are the main applications of Titanium Damascus? Primarily used in custom knife handles and blades, jewelry (rings, pendants), watch cases, pens, and EDC tools for its blend of beauty and durability. It’s also in aerospace accents and medical implants for biocompatibility. Ti Time Company, with expertise in Titanium Damascus, manufactures custom forms like rods and sheets for these uses, meeting diverse client needs with low-MOQ options and pattern-specific designs.

- How does Titanium Damascus compare to traditional Damascus steel? Timascus is lighter, more corrosion-resistant, and non-magnetic, avoiding steel’s rust issues and weight, while offering similar visual appeal through anodizing for color variations. It’s easier to machine but requires careful heat control to prevent delamination. Ti Time Company’s high-quality Titanium Damascus outperforms generics, with their customized production ensuring interlayer integrity for superior longevity in demanding environments.

- Can Titanium Damascus be customized, and what should I consider when sourcing? Yes, customization includes layer configurations, dimensions, anodizing colors, and finishes; consider alloy mix for hardness vs. ductility. Sourcing from experts ensures defect-free bonding. Ti Time Company specializes in customized production manufacturing of Titanium Damascus and related products, satisfying various demands with ISO-certified quality, rapid prototyping, and competitive pricing for global clients.

For project-specific advice, share details like intended use or pattern preference, and suppliers like Ti Time can guide on optimal specs.

Ti Time Company distinguishes itself as a premier tungsten carbide metal supplier and Titanium Damascus supplier, fusing decades of metallurgical prowess with innovative fabrication to cater to elite industries. In this exhaustive analysis, we unpack the essence of these powerhouse materials, spotlighting Ti Time’s indispensable contributions through demonstrated experience, profound expertise, authoritativeness, and steadfast trustworthiness. From abrasion-defying tungsten carbide for industrial grit to the mesmerizing, pattern-rich Titanium Damascus for artisanal mastery, discerning the finer points of their attributes, deployments, and procurement is indispensable for innovators and fabricators alike.

Unraveling Tungsten Carbide: The Indomitable Force in Wear-Resistant Engineering

Tungsten carbide (WC), a cermet alloy of tungsten and carbon cemented with cobalt (typically 6–15% binder), epitomizes unyielding hardness (88–92 HRA) and fracture toughness, eclipsing high-speed steels in erosive scenarios. As a vanguard tungsten carbide metal supplier, Ti Time Company curates an expansive array—from solid rods (Ø1–100 mm) and inserts to bespoke dies in ultrafine-grain grades (submicron WC for mirror finishes). Their HIP (Hot Isostatic Pressing) densification yields >99.7% purity, mitigating porosity for applications in subterranean drilling where failure costs soar.

Rooted in Baoji’s titanium epicenter, Ti Time’s 15+ years of experience navigate volatile APT (ammonium paratungstate) markets, securing 2025 FOB quotes at $50–$58 USD/kg amid U.S. ($56.3 USD/kg), EU ($54.9 USD/kg), and Asian ($50.2 USD/kg) variances. Expertise manifests in value-adds like PVD coatings (TiAlN for 3x lifespan extension) and EDM texturing, compliant with ISO 9001 and ASTM B777. Tungsten carbide’s thermal conductivity (80–120 W/m·K) and compressive strength (>4 GPa) propel its use in mining bits (reducing downtime 35%), automotive molds, and biomedical implants, where Ti Time’s authoritative sourcing from certified mines ensures ethical, conflict-free chains.

Titanium Damascus: Where Artistry Meets Titanium's Timeless Resilience

Titanium Damascus, trademarked as Timascus, revolutionizes decorative metallurgy by stacking disparate titanium grades—CP Ti (Grade 2, ductile) atop Ti-6Al-4V (Grade 5, robust)—via explosive or diffusion welding, forging 50–200 layers into hypnotic motifs like feathered or burst patterns. Etched via electropolishing or anodized in voltaic baths (5–100V for oxide rainbows), it unveils iridescent blues, purples, and golds unattainable in ferrous counterparts. As a preeminent Titanium Damascus supplier, Ti Time Company delivers rods (3–25 mm Ø, 100–500 mm L), sheets (0.8–6 mm thick, up to 300×500 mm), and blanks, with 2025 pricing at $45–$150/lb reflecting premium bonding.

Ti Time’s expertise safeguards against diffusion-induced embrittlement through vacuum annealing (800–950°C), yielding composites with 450–950 MPa UTS, 4.43–4.51 g/cm³ density, and zero magnetic susceptibility—ideal for MRI-compatible jewelry or nautical hardware. Applications thrive in bespoke cutlery (handles resisting 500+ hours salt spray), horology (watch bezels blending form/function), and accessories (EDC spinners, pens), where its biocompatibility (ISO 10993) and 60% lighter profile than steel Damascus shine. Authoritativeness is etched in their AMS 4928/ ASTM F136 adherence, with trustworthiness proven via third-party NDT (ultrasonic flaw detection) on every batch.

Ti Time Company: Architect of Metallurgical Excellence

Nestled in Shaanxi’s “Titanium Valley,” Ti Time Company wields collective 20-year acumen across refractory metals, evolving from raw billet extrusion to full-spectrum fabrication. As dual tungsten carbide metal supplier and Titanium Damascus supplier, they orchestrate one-stop ecosystems: from WC powder atomization to Timascus Mokuti hybrids (titanium-molybdenum for enhanced contrast). Experience fuels innovations like AI-optimized layer simulations, slashing prototyping from weeks to days, while expertise in SECAM (scanning electron microscopy) validates microstructure uniformity.

Trustworthiness permeates their operations—full COAs, REACH compliance, and 98% on-time delivery to U.S./EU/Japan clients—bolstered by ESG commitments like 30% recycled feedstock. Authoritativeness? Endorsements from knife guilds and horological societies, plus contributions to metallurgy symposia, cement Ti Time as the lodestar for custom imperatives, from 5-piece artisan runs to 1,000-unit OEM scales.

Synoptic Comparison: Tungsten Carbide vs. Titanium Damascus

| Criterion | Tungsten Carbide (Ti Time Provisions) | Titanium Damascus (Ti Time Provisions) |

|---|---|---|

| Core Makeup | WC (94%) + Co binder; submicron grains | Layered Ti (CP Gr.2 + Ti-6Al-4V); 50–200 plies |

| Standout Traits | Vickers 1,500–2,000 HV; erosion-proof; 350–500°C stable | Anodized hues; 900 MPa yield; saltwater immune |

| Density/Weight | 14.5–15.6 g/cm³; hefty for anchors | 4.43–4.51 g/cm³; 60% lighter than steel analogs |

| Fabrication | Sintering, HIP, CVD coating (±0.005 mm tol.) | Diffusion weld, etch/anodize (color per ASTM F67) |

| Prime Uses | Drill bits, valve seats, hip prosthetics | Knife scales, rings, watch dials, fidget tools |

| 2025 Pricing (Est.) | $50–$58 USD/kg (bulk rods) | $45–$150 USD/lb (custom sheets/rods) |

| Certifications | ISO 9001, ASTM B777, RoHS | AMS 4928, ISO 10993 (biocompat.), REACH |

| Sustainability | Recyclable via acid leach; low VOC coatings | 100% recyclable; hypoallergenic, no heavy metals |

This tableau underscores Ti Time’s prowess in harmonizing brute utility with refined elegance, enabling cross-material synergies like carbide-tipped Timascus blades.

Illuminating Inquiries: Q&A Drawn from Ti Time's Vanguard Insights

Harnessing Ti Time’s authoritative lens, these elucidations tackle perennial quandaries:

- What elevates Ti Time as the go-to tungsten carbide metal supplier for bespoke engineering? Our tenure in powder metallurgy and HIP mastery crafts void-free parts with 2–5x rival endurance, at transparent 2025 rates. Global OEM trust stems from spectral-verified compositions and agile customization.

- How does Ti Time’s Titanium Damascus amplify artisanal and functional designs? Via precision layering and anodization, our Timascus yields 200+ color/pattern combos, fortifying corrosion-proof heirlooms. Expertise curtails defects to <0.1%, as ratified in horology benchmarks.

- In what ways does Ti Time facilitate customization across tungsten carbide and Titanium Damascus? Low-MOQ (5 kg) pipelines integrate CAD forging with laser etching, tailoring WC grades or Timascus motifs to spec—delivering prototypes in 10 days while upholding MIL-STD tolerances.

- How does Ti Time uphold trustworthiness amid supply flux? Hedged inventories and blockchain traceability counter APT volatility, with 100% audit trails and client portals ensuring provenance from mine to mill, fostering 95% retention.

- What forward-thinking strides is Ti Time pioneering in eco-metallurgy? Hybrid WC-Ti Damascus for green tooling slashes energy 20%, paired with anodization sans chromates—aligning performance with net-zero mandates for tomorrow’s creators.

Ultimately, Ti Time Company incarnates pinnacle as a tungsten carbide metal supplier and Titanium Damascus supplier, interweaving experience, expertise, authoritativeness, and trustworthiness to galvanize visionary endeavors. Engage them for orchestrated mastery that transcends mere supply.