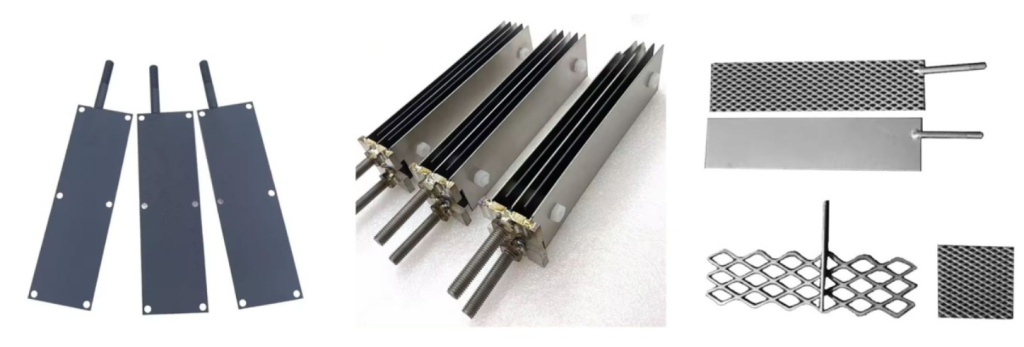

What Is Titanium Electrode Manufacturing?

Titanium electrode manufacturing is a multi-stage process that transforms titanium substrates into high-performance electrochemical electrodes by applying a series of precious metal oxide (PMO) coatings. These electrodes are extensively used in industries such as water treatment, chlor-alkali production, electroplating, and cathodic protection.

Ti Time Company’s Manufacturing Capabilities

1. Substrate Preparation

We begin with high-purity TA1-grade titanium sheets, meshes, or tubes. The substrate is cleaned, annealed, leveled, and acid-pickled to achieve a uniform, contamination-free surface ideal for coating adhesion.

2. Advanced Coating Techniques

We use multiple coating methods based on customer requirements and performance goals:

Thermal Decomposition – Most widely used; involves applying metal salt solution and sintering repeatedly.

Sol-Gel Process – Produces ultra-fine, crack-resistant coatings for advanced applications.

Electrodeposition – For uniform, dense coatings on complex geometries.

Sputtering – High-tech PVD technique for ultra-pure, precision-coated electrodes.

3. Multilayer Coating & Sintering

Up to 20 layers of coatings (e.g., RuO₂, IrO₂, Pt) are applied, with intermediate heat treatment at 450–550°C to build catalytic activity, crack resistance, and long service life.

4. Quality Control & Performance Testing

Each electrode is tested for coating thickness, adhesion, electrochemical activity, and accelerated aging/life-cycle tests before packaging.

Why Choose Ti Time Company for Titanium Electrodes?

✅ Expertise: 15+ years of specialized experience in titanium and PMO coatings

✅ Customization: Full support for tailored formulas, shapes, and coatings

✅ Certifications: ISO 9001:2015, RoHS-compliant coatings, CE-certified

✅ Global Supply: Fast delivery and support across Asia, Europe, North America

✅ Industries Served: Chlorine generation, electroplating, electrolysis, water disinfection, and more

FAQs About Titanium Electrode Manufacturing

What is the main advantage of titanium electrodes?

They offer high conductivity, long service life, and excellent resistance to corrosion and passivation, even in harsh electrolytic environments.

How many coating layers are typically applied?

Between 17–20 cycles of coating and sintering are applied to ensure uniform performance and durability.

What precious metal oxides are used in the coating?

We offer coatings based on ruthenium, iridium, platinum, and their combinations, depending on electrochemical application and pH conditions.

Can Ti Time Company produce custom sizes and geometries?

Yes. We manufacture electrodes in mesh, plate, rod, tube, and custom forms as per technical drawings and specifications.

What is the lifespan of a typical Ti Time electrode?

Depending on the electrolyte and current density, our electrodes can last 2 to 5 years or longer, with low maintenance and high stability.