Titanium Electrode Plates: Pioneering Efficiency in Electrochemical Processes

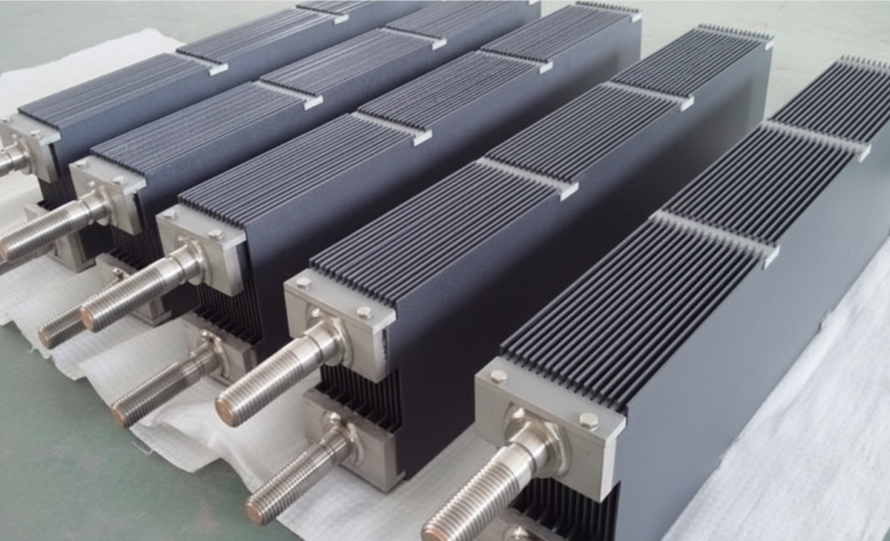

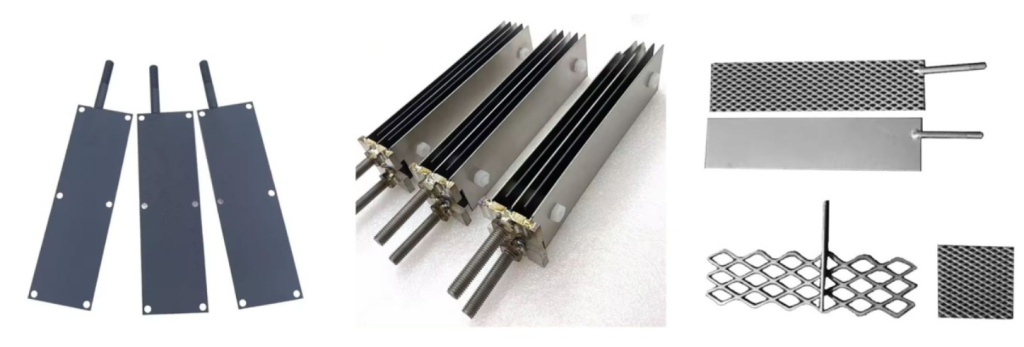

Titanium electrode plates have emerged as a cornerstone material in modern electrochemical applications, offering unparalleled performance in demanding environments. Crafted from titanium and its alloys, these plates are enhanced with specialized coatings such as Ir-Ta (Iridium-Tantalum) and Ru-Ir (Ruthenium-Iridium) to boost conductivity and corrosion resistance.

Key Features and Applications

- High Conductivity & Durability: The Ir-Ta coating significantly elevates electrical conductivity, making titanium ideal for large-scale processes like hydrogen production via water electrolysis and chlor-alkali electrolysis for chlorine and caustic soda.

- Extreme Corrosion Resistance: Withstanding harsh acidic or alkaline conditions, these plates are vital for electrochemical synthesis, water treatment, and industrial electroplating.

- Mechanical Strength: Titanium’s robustness ensures reliability under physical stress, even in high-throughput systems.

Global Market Leadership

China dominates the production of titanium electrode plates, with companies like TITIME leading innovation through customizable solutions tailored to industrial and research needs.

Understanding the HS Code for Titanium Electrodes: 8108 vs. 8543.90

Accurate classification of titanium electrodes under the Harmonized System (HS) is critical for global trade compliance. The HS code depends on the electrode’s form and application:

HS Code 8108.90:

- Covers titanium products, including plates, rods, and waste.

- Ideal for raw or semi-finished titanium electrode plates (e.g., uncoated or coated for general use).

- Example: A titanium electrode plate coated with Ir-Ta for chlor-alkali production falls under 8108.90.

HS Code 8543.90:

- Applies to electrical machinery parts, including electrodes designed for specific devices.

- Suitable for pre-assembled or application-specific electrodes (e.g., those integrated into electrolysis cells).

Why It Matters: Misclassification can lead to customs delays or fines. Manufacturers and exporters must consult local authorities to ensure alignment with product specifications.

Titanium Electrode Holders: Precision Engineering for Research and Industry

Titanium electrode holders are indispensable tools for securing and stabilizing electrodes during experiments and industrial processes. Designed with corrosion-resistant materials like PTFE (Polytetrafluoroethylene) and conductive metals, these holders ensure reliable performance in harsh conditions.

Top Products in the Market

StonyLab Titanium Electrode Holder:

- Features a 99.95% pure titanium base and PTFE casing.

- Compatible with 0.1–5mm samples, SGS-certified for quality.

- Ideal for electrochemical systems and material science research.

Labasics PTFE Titanium Holder:

- Includes a 10x15mm titanium plate and gold-plated copper rods for conductivity.

- Flexible design for diverse testing scenarios but lacks replaceable titanium plates.

JJ110 PTFE Multifunctional Holder:

- Affordable option for basic experiments, though limited in high-stress applications.

Applications Across Industries

- Research: Used in universities and labs for electrochemical studies.

- Industrial Electrolysis: Supports large-scale systems for hydrogen and chlorine production.

- Water Treatment: Facilitates electrocoagulation and electrooxidation processes.

The Future of Electrochemical Innovation

As industries prioritize sustainability and efficiency, titanium electrode plates, precise HS coding, and advanced holders will remain pivotal. With China’s manufacturing prowess and global demand for clean energy solutions, the market is poised for exponential growth.

Key Takeaways:

- Titanium Electrode Plates: Optimal for high-conductivity, corrosion-resistant applications.

- HS Code Compliance: Essential for seamless international trade.

- Advanced Holders: Enhance precision and safety in electrochemical workflows.