Titanium Electrodes in Saltwater Technology: A Complete Guide

Titanium electrodes are essential components in many modern electrochemical systems, especially in water treatment applications. Their ability to convert salt into chlorine and resist corrosion makes them the preferred material in saltwater chlorinators and Intex saltwater systems. This article explores their uses, lifespan indicators, potential properties, and advanced industrial applications.

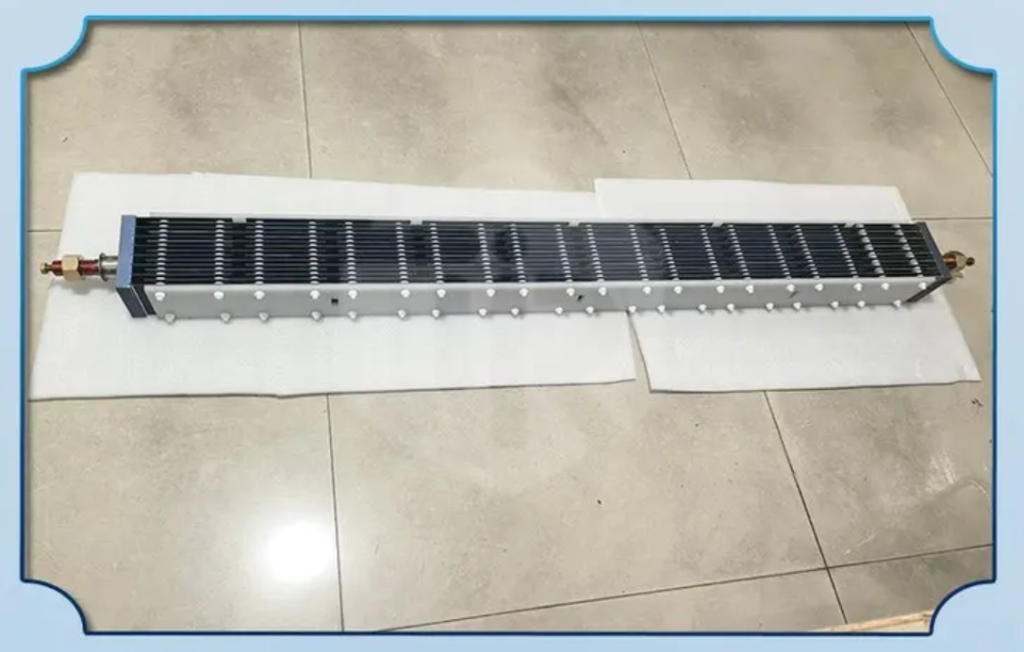

1. Titanium Electrode for Intex Saltwater System

Intex saltwater systems use titanium electrodes as core elements in the salt-to-chlorine conversion process through electrolysis.

✅ Functionality

Converts sodium chloride (NaCl) into chlorine gas (Cl₂), which sanitizes pool water effectively.

Located within the electrolytic cell of the saltwater generator.

✅ Electrode Lifespan

Average operating lifespan: ~12,000 hours

Example: 8 hours/day × 365 days/year × 4 years ≈ 11,680 hours

✅ Replacement Indicators

Coating Wear: When over 30% of the black/grey surface coating has worn off.

Reduced Oxygen Output: DO (Dissolved Oxygen) levels drop below 6.0 ppm.

Lack of Bubble Production: Fewer visible bubbles mean less electrolytic action.

Decline in Water Clarity: If the pool needs more chemical assistance, the electrodes may be failing.

✅ Maintenance Tips

Conduct visual inspections regularly.

Send photos to the manufacturer if unsure about performance.

Keep the chamber clean to avoid scaling and buildup.

2. Titanium Electrode Potential in Energy Applications

Titanium’s electrochemical potential is key in battery and energy storage applications.

⚡ Breakthrough Example: KTiPO₄F

Exhibits a redox potential of 3.6V in potassium-ion batteries—far higher than traditional titanium-based materials.

⚙️ Mechanisms Behind the Elevated Potential

Inductive Effects: Multiple anions shift the redox potential upward.

Charge/Vacancy Ordering: Strategic atomic-level arrangement boosts performance.

✅ Performance Benefits

High-rate Stability: No capacity loss even after 100 cycles at 5C.

Low Ion Migration Barriers: Only 0.2 eV, ensuring fast charge/discharge.

Carbon Coated Variants: Improved cycling and conductivity.

3. Titanium Electrode for Salt Chlorinators

Salt chlorinators also rely on titanium electrodes to convert salt into chlorine automatically.

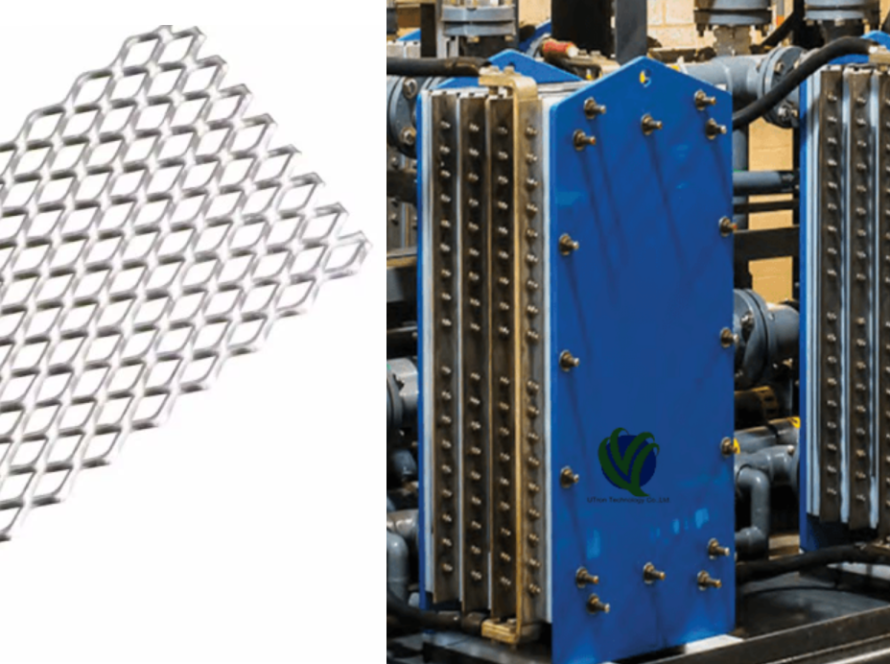

🧱 Construction & Composition

Substrate: Grade 1 or Grade 2 pure titanium

Coating: Ruthenium oxide, iridium oxide, or platinum

These coatings enhance conductivity and durability.

📐 Technical Specifications (Example Models)

| Model | Length (cm) | Width (cm) | Current Output | Chlorine Production (g/h) |

|---|---|---|---|---|

| U-RP50 | 25 | 6 | 27A | 50 |

| U-RP35 | 20 | 6 | 21A | 35 |

| U-RP25 | 13 | 6 | 14A | 25 |

| U-RP20 | 11 | 6 | 12A | 20 |

🌊 Key Features

Self-Cleaning: Polarity reversal minimizes scaling.

Scale Resistance: Special cathode surfaces resist hard water build-up.

Algae Prevention: Constant chlorine production inhibits growth.

Modular Design: Easy replacement of worn components.

4. Benefits of Titanium Electrodes

✅ Corrosion Resistance

Ideal for use in saline and acidic environments.

✅ Electrical Conductivity

Enhances current flow when paired with noble metal coatings.

✅ Thermal Stability

Operates safely under high-temperature conditions.

✅ Strength-to-Weight Ratio

Lightweight yet durable, simplifying installation and minimizing structural load.

5. Applications Beyond Pools

Titanium electrodes are widely used in:

Battery Technologies: Including next-gen lithium- and potassium-ion batteries.

Water Electrolysis: Hydrogen production and industrial electrolysis.

Wastewater Treatment: Degradation of pollutants and metals.

Seawater Desalination: Long-term stability under marine conditions.

Titanium electrodes represent a fusion of chemical resilience and electrochemical efficiency. Whether for backyard pool sanitation or high-performance energy systems, their versatility continues to drive innovation. Understanding their function, potential, and maintenance requirements ensures extended usage and optimal system output.

As new materials and coating technologies emerge, titanium electrodes will likely become even more integral in sustainable technology and energy solutions.

At Ti Time, we pride ourselves on being a leading manufacturer and supplier in the global metal materials industry. With years of expertise and a commitment to innovation, we specialize in the custom production of titanium electrodes for Intex saltwater systems, high-performance titanium electrodes for salt chlorinators, and advanced materials designed to enhance titanium electrode potential in energy storage and electrochemical applications. Whether you’re in need of tailored solutions for residential water treatment or cutting-edge industrial components, Ti Time delivers reliability, durability, and precision-engineered titanium products that meet the highest standards of performance.