In the world of advanced materials, Titanium Electrodes and Anodes stand out as critical components driving efficiency in modern industry. From large-scale seawater desalination to the precision required in medical devices, these materials are the backbone of electrochemical applications.

Their unique ability to withstand harsh environments while maintaining high electrical performance makes them indispensable for everything from battery manufacturing to environmental protection. This article delves into the key characteristics, the intricate manufacturing process, and the diverse applications of titanium anodes.

Key Characteristics: Why Industry Prefers Titanium

Titanium electrodes are not just defined by the metal itself, but by the performance advantages they offer over traditional materials (like graphite or lead).

1. Superior Corrosion Resistance

Titanium possesses a natural immunity to aggressive environments. These electrodes can operate stably for long periods in highly acidic or alkaline solutions, resisting the degradation that typically destroys other metals. This extends the lifespan of the equipment significantly.

2. Excellent Electrical Conductivity

Efficiency is paramount in electrolysis. Titanium is a robust conductor, allowing these electrodes to support the high current densities required for various electrochemical reactions without significant energy loss.

3. High-Temperature Stability

Industrial processes often generate high heat. Titanium anodes maintain their structural integrity and electrochemical performance in high-temperature environments, resisting deformation, warping, or active layer shedding.

4. High Strength-to-Weight Ratio

Titanium is renowned for being lightweight yet incredibly strong. Using titanium electrodes reduces the overall weight of the equipment without compromising structural durability, making them ideal for weight-sensitive applications like aerospace.

The Manufacturing Process

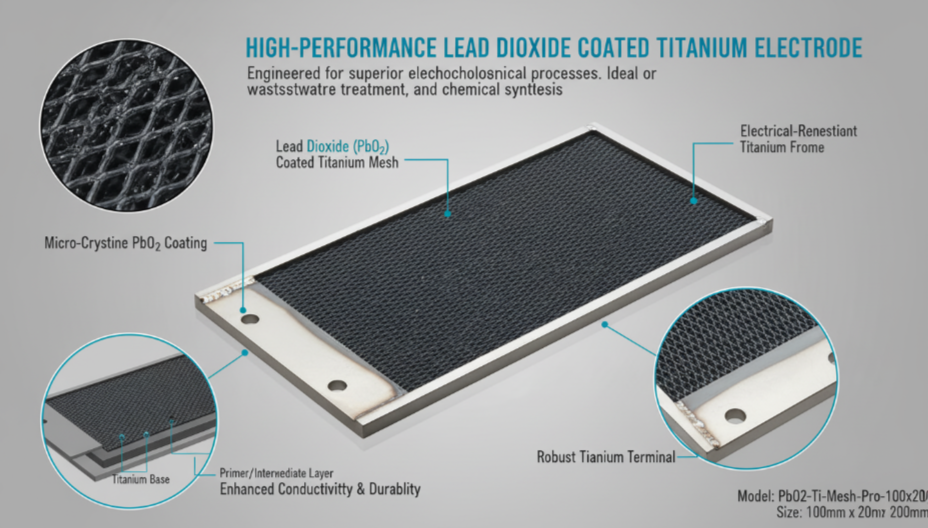

Creating a high-performance titanium anode is a precision engineering process. It generally involves the following five critical steps:

Material Selection: The process begins with selecting high-purity titanium. The raw material must be free of impurities and defects to ensure the final electrode has a uniform current distribution and structural integrity.

Machining and Shaping: The raw titanium plates are cut, drilled, and machined into specific shapes and dimensions required by the client’s design. This is the structural foundation of the anode.

Surface Treatment: To enhance the binding force of the coating and the surface activity, the titanium undergoes physicochemical or electrochemical treatments. This step is vital for increasing the surface area and preparing the substrate.

Platinum Coating (Activation): To boost electrocatalytic performance, a layer of Platinum (or other noble metal oxides) is plated onto the titanium surface. This coating allows the electrode to facilitate chemical reactions more efficiently.

Assembly and Welding: Finally, the processed components are assembled according to design specifications, typically using precision welding techniques to ensure a solid electrical and mechanical connection.

Industrial Applications

The versatility of titanium electrodes allows them to be deployed across a vast spectrum of industries.

1. Electrochemical Industry

This is the primary home for titanium anodes. They are essential in:

Batteries: Enhancing energy storage efficiency.

Electrolyzers: Used in Chlor-alkali industry and water electrolysis for hydrogen production.

2. Industrial Processing & Metallurgy

Metal Extraction: Used in the electrowinning of metals (recovering metals from solution).

Desalination: Critical for electrodialysis processes that turn seawater into fresh water.

Catalysis: They accelerate reaction rates and improve yield in various chemical synthesis processes.

3. Environmental Protection

Titanium anodes play a hero’s role in green technology:

Wastewater Treatment: They are used to degrade organic pollutants and treat industrial sewage.

Sanitization: reducing harmful substances in water systems effectively.

4. Medical Technology

While structural titanium is famous for artificial joints and bone plates, titanium electrodes specifically are used in active medical devices, such as components for cardiac pacemakers, where reliability and biocompatibility are non-negotiable.

5. Aerospace Engineering

Leveraging their high strength and low density, titanium electrodes and related components are utilized in the manufacturing of aircraft and satellites, contributing to lighter, more fuel-efficient aerospace vehicles.

Titanium electrodes and anodes represent the perfect synergy of durability and efficiency. Whether it is ensuring clean water, powering the next generation of batteries, or aiding in medical recovery, their impact is profound. As manufacturing technologies evolve, we can expect the applications of this versatile material to expand further, driving innovation in global industrial production.