Electrolysis, the process of using electricity to drive non-spontaneous chemical reactions, is fundamental to numerous industrial processes, from chemical production to water treatment and clean energy generation. Central to the efficiency and success of these processes are the electrodes used. Among the most versatile and reliable materials available, titanium electrodes for electrolysis stand out due to their unique combination of properties.

Drawing on deep expertise in material science and electrochemical engineering, this guide provides an authoritative overview of titanium electrodes used in electrolysis. We will explore the different types, their advantages, recent advancements, and practical considerations, establishing the trustworthiness needed when selecting these critical components. Furthermore, we’ll highlight how specialist manufacturers like Ti Time offer customized solutions based on extensive experience.

Why Titanium is an Ideal Substrate for Electrolysis Electrodes

Titanium possesses inherent characteristics that make it an excellent base material for electrodes:

- Exceptional Corrosion Resistance: It forms a stable, passive oxide layer (TiO₂) that protects it from attack in many aggressive electrolytes (acidic, alkaline, saline).

- Good Electrical Conductivity: Allows efficient current transfer.

- Mechanical Strength & Durability: Provides a robust physical structure.

- Lightweight: Offers handling and design advantages.

However, it’s crucial to understand that while pure titanium excels as a cathode (where reduction occurs), its native oxide layer is insulating. This limits its effectiveness as an anode (where oxidation occurs) at higher voltages unless enhanced with specific coatings.

Types of Titanium Electrodes for Electrolysis: The Importance of Coatings

The true versatility of titanium electrodes in electrolysis comes from specialized coatings applied to the titanium substrate. These coatings provide the necessary catalytic activity and enhance stability for anodic reactions

1. Pure Titanium Electrodes

- Use: Primarily as cathodes in applications like electroplating or as substrates for other coatings.

- Properties: Strong, wear-resistant, corrosion-resistant in cathodic conditions. Forms insulating layer if used anodically at significant potential.

2. Platinum-Coated Titanium Electrodes

- Use: Widely used as anodes and cathodes for high-efficiency electrolysis (e.g., hydrogen production via water electrolysis, water ionizers, electrochlorination).

- Properties: Thin platinum layer (e.g., 0.25-5 microns) provides high catalytic activity, excellent conductivity, and stability. Combines Pt performance with Ti’s cost-effectiveness/strength.

3. Iridium-Tantalum-Titanium Electrodes

- Use: Often employed as dimensionally stable anodes (DSAs) in demanding applications like electrochemical synthesis, oxygen evolution reactions, or certain water treatment processes.

- Properties: Mixed Metal Oxide (MMO) coating containing iridium and tantalum offers superior corrosion resistance (especially in acids) and high catalytic activity.

4. MnO₂/PbO₂ Coated Titanium Anodes

- Use: Cost-effective anode options for specific applications like chlorate production or certain wastewater treatments where precious metals might not be required or optimal.

- Properties: Provide necessary conductivity and catalytic surfaces for specific anodic reactions.

(Referencing the summary table provided in the source material reinforces these points regarding corrosion resistance, catalytic activity, conductivity, typical use, and relative cost.)

Key Advantages Summarized

Using titanium-based electrodes in electrolysis offers significant benefits:

- Durability & Longevity: High corrosion resistance leads to longer service life and reduced maintenance downtime.

- Efficiency: Good conductivity and (with coatings) high catalytic activity improve reaction rates and lower energy consumption.

- Versatility: Suitable for diverse processes like chlor-alkali production, metal plating/recovery, wastewater treatment, cathodic protection, and hydrogen generation.

- Environmental Profile: Titanium is non-toxic and relatively abundant, offering a more environmentally sound option compared to some heavy metal electrodes.

Advancements in Titanium Electrode Technology

The field is continuously evolving. Recent developments, such as the collaborative work between Mitsubishi Materials Corporation and Yokohama National University on a novel double-layer structure titanium electrode, demonstrate this progress. This innovation aims to improve electrolysis efficiency specifically under high current densities. A key goal is potentially reducing the reliance on expensive precious metal catalysts, which could significantly lower the cost of processes like green hydrogen production – showcasing experience driving innovation.

Frequently Asked Questions

What are the advantages of using platinum-coated titanium electrodes?

They offer a powerful combination: the high catalytic activity, excellent electrical conductivity, and chemical stability of platinum, coupled with the mechanical strength, corrosion resistance (as a base), and lower overall cost of using titanium as a substrate instead of solid platinum. This leads to highly efficient and durable performance in applications like hydrogen generation and water treatment.

How does the new double-layer titanium electrode improve efficiency?

According to reports, the newly developed double-layer structure specifically enhances performance and efficiency when operating under high current densities. This is crucial for industrial-scale electrolysis where high throughput is desired. By improving efficiency under these demanding conditions, it may also enable reductions in the amount of precious metal catalyst needed, potentially lowering costs.

Choosing the Right Electrode & Custom Solutions from Ti Time

Selecting the optimal titanium electrode for electrolysis depends on the specific process: the electrolyte chemistry, target reaction (e.g., chlorine vs. oxygen evolution), required current density, temperature, and budget.

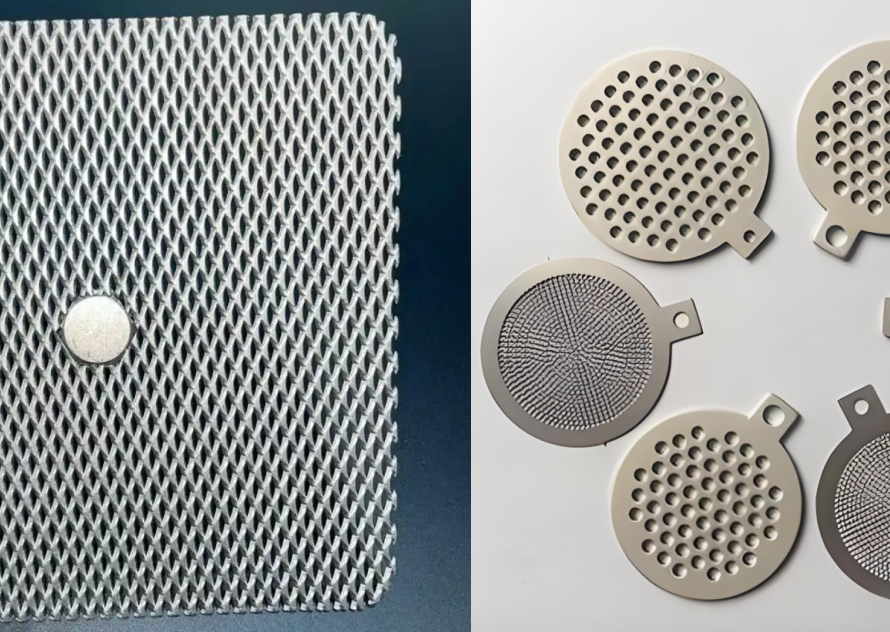

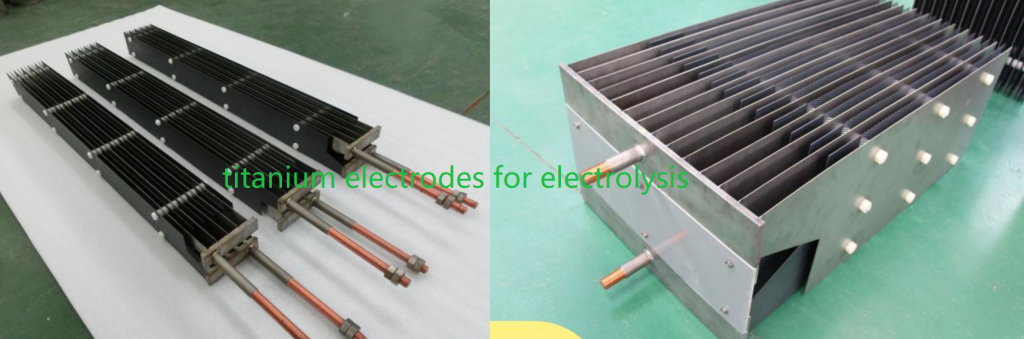

For standard applications or unique process requirements, partnering with an experienced manufacturer is crucial. Ti Time is a leading manufacturer and supplier specializing in titanium materials and holds significant expertise in the custom production of various “titanium electrodes for electrolysis”. Leveraging their experience, they can manufacture electrodes in diverse forms (mesh, plate, rod, tubular, wire) with specific coatings (Pt, MMO, etc.) and dimensions tailored precisely to your needs. This authoritative capability ensures you receive a trustworthy and optimized solution for your electrolysis system.

Titanium electrodes, particularly when enhanced with carefully selected catalytic coatings, are indispensable tools in modern electrolysis. Their inherent corrosion resistance and strength, combined with the tailored performance offered by coatings like platinum or mixed metal oxides, provide durable, efficient, and versatile solutions across countless industrial applications. Ongoing advancements promise further improvements in efficiency and cost-effectiveness. For reliable performance, choosing the right electrode type and sourcing from a reputable manufacturer capable of providing high-quality standard or custom solutions, such as Ti Time, is paramount.