Titanium fabrication is a complex, multi-stage process that transforms raw titanium ore into high-performance components for aerospace, medical, industrial, and defense applications. From extraction and alloying to cutting, forming, and finishing, titanium fabrication demands metallurgical expertise, precision equipment, and strict quality control.

As a global titanium supplier and fabricator, Ti Time Company provides custom titanium solutions, including raw materials and fully fabricated parts, tailored to meet the highest industry standards.

1. Experience: From Ore to Engineered Solutions

With over 20 years of industry experience, Ti Time Company supports end-to-end titanium production—from sponge processing to precision-machined parts. We serve clients in aerospace, medical, petrochemical, and marine sectors, offering unmatched expertise in fabrication processes and alloy selection.

2. Titanium Fabrication Process Overview

✅ 1. Extraction & Sponge Production

Titanium is extracted from ilmenite and rutile ores.

Using the Kroll process, titanium dioxide is converted to titanium tetrachloride (TiCl₄), then reduced with magnesium or sodium to create titanium sponge.

✅ 2. Alloying & Melting

Sponge is alloyed with elements like aluminum, vanadium, and molybdenum for specific properties.

Techniques such as Vacuum Arc Remelting (VAR) and Electron Beam Melting (EBM) produce homogeneous, high-purity titanium ingots.

✅ 3. Forming & Shaping

Forging: Hot-forged billets are shaped for strength and grain refinement.

Casting: Used for near-net shapes, typically in cost-sensitive applications.

Hot Forming: Improves formability, reduces springback.

Superplastic Forming: Produces intricate parts under high-temperature and gas pressure.

Cold Forming: Enables simpler shapes but requires post-processing to reduce stress.

✅ 4. Machining & Cutting

Titanium’s hardness requires special tooling and methods like:

CNC machining

Waterjet cutting

Laser cutting

Ti Time provides tight-tolerance fabrication for mission-critical parts.

✅ 5. Heat Treatment

Includes annealing, stress relieving, and aging to optimize strength, toughness, and fatigue resistance.

Adjusts microstructure (α/β phase balance) in titanium alloys like Ti-6Al-4V.

3. Applications of Fabricated Titanium

| Industry | Application |

|---|---|

| Aerospace | Structural parts, fasteners, engine components |

| Medical | Implants, surgical instruments, prosthetics |

| Defense | Armor, ballistic panels, corrosion-resistant structural parts |

| Industrial | Heat exchangers, pressure vessels, desalination components |

| Automotive | High-strength lightweight parts for motorsports and EVs |

4. Why Choose Ti Time Company?

✅ Raw Material to Finished Product – Sponge, ingots, forged blanks, and precision parts

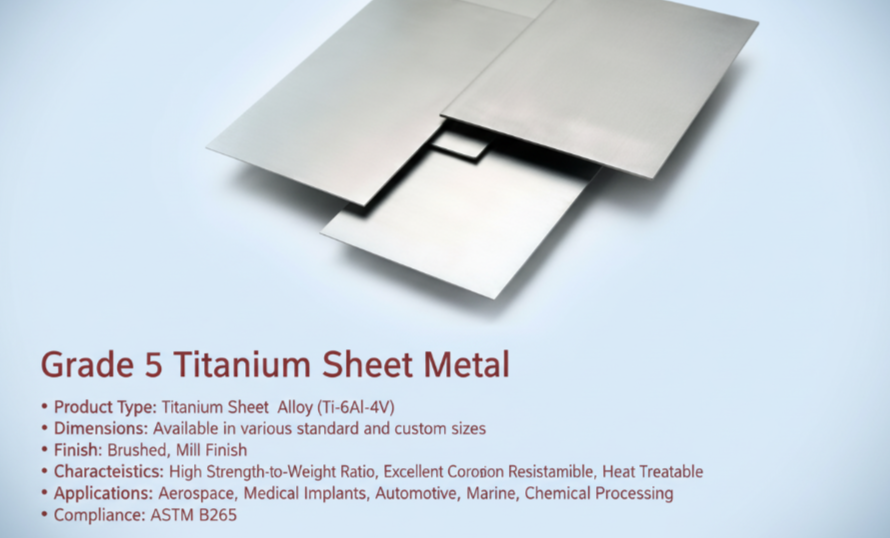

✅ Custom Alloy Formulations – Including Grade 2, Grade 5 (Ti-6Al-4V), Grade 23, and others

✅ Cutting-Edge Fabrication – CNC, EDM, 5-axis machining, superplastic forming

✅ Certifications – ASTM, ISO, AS9100, medical-grade MTRs

✅ Global Supply Chain – Fast delivery and scalable production

FAQs – Titanium Fabrication

What’s the difference between cold forming and hot forming titanium?

Cold forming is done at room temperature and may cause springback or cracking. Hot forming, done at elevated temperatures, improves formability and structural integrity.

Can titanium be cast like aluminum?

Yes, but titanium casting requires vacuum or inert gas environments due to its high reactivity, and results in different grain structures than forging.

What is superplastic forming in titanium?

A process that shapes titanium at very high temperatures and low strain rates, allowing complex geometries without mechanical stress.

What are the most commonly fabricated titanium alloys?

Ti-6Al-4V (Grade 5) is the most common due to its strength and versatility. Others include Grade 2 (CP titanium) and Ti-6Al-7Nb for medical use.

Does Ti Time Company provide custom titanium components?

Absolutely. We offer custom cutting, machining, and finishing services for titanium components across industries.

Titanium fabrication is a sophisticated process that transforms a reactive, high-performance metal into engineered components used in some of the world’s most demanding environments. From initial sponge to final product, each stage requires metallurgical precision, advanced tooling, and certified quality.

At Ti Time Company, we deliver comprehensive titanium solutions, combining expertise, experience, and end-to-end capabilities to support projects from concept to completion.