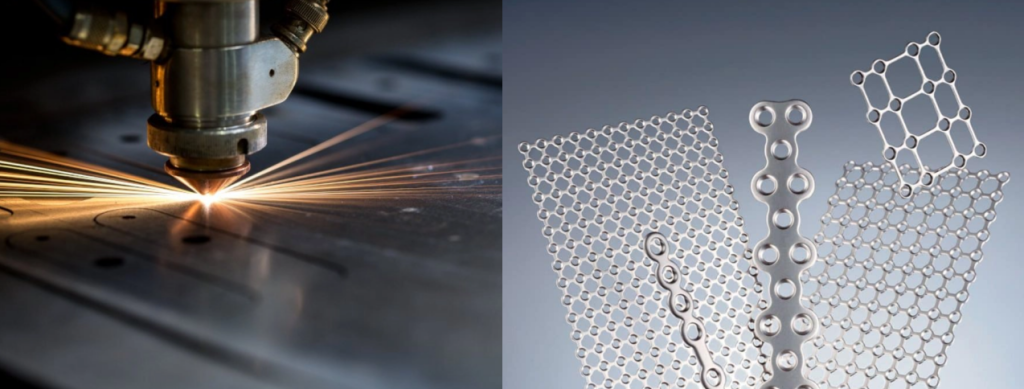

Titanium laser cutting is a precision-driven, non-contact manufacturing process that leverages high-energy laser beams to slice through titanium materials with minimal distortion and exceptional accuracy. This advanced technique enables the production of clean-edged, complex parts from titanium sheets, foils, and plates—making it ideal for industries demanding performance and reliability.

At Ti Time Company, we not only supply high-grade titanium but also provide precision laser cutting services tailored to aerospace, medical, defense, and industrial applications.

1. Experience: Advanced Cutting Services from Titanium Experts

With decades of experience in titanium processing and alloy development, Ti Time Company offers laser cutting services built on metallurgical knowledge and cutting-edge CNC automation. Our facilities support CO₂ and fiber laser systems, ensuring tight tolerances, repeatability, and smooth finishes across all grades of titanium.

2. How Titanium Laser Cutting Works

A high-intensity laser beam is focused on the titanium surface, melting or vaporizing the material along a pre-programmed path.

Assist gases like nitrogen or argon prevent oxidation and improve cutting efficiency.

CNC-controlled laser machines guide the laser with micrometer precision for consistent, intricate cuts—even in titanium plates up to 20 mm thick.

3. Key Advantages of Titanium Laser Cutting

| Benefit | Description |

|---|---|

| Extreme Precision | Tolerances as tight as ±0.0005” for intricate components |

| High Efficiency | Fast cutting speed reduces production time and labor costs |

| Minimal Heat-Affected Zone | Prevents material warping and preserves corrosion resistance |

| Reduced Material Waste | Fine laser kerf minimizes scrap—vital for expensive metals like titanium |

| Surface Quality | Clean, burr-free edges requiring little to no secondary finishing |

4. Applications of Titanium Laser Cutting

Aerospace: Engine brackets, structural panels, turbine components

Medical: Surgical tools, implants, bone plates, and prosthetics

Defense: Armor plates, military-grade brackets, ballistic components

Electronics: Precision housings, connectors, shielding

Consumer Goods: Titanium watch components, eyewear frames, luxury tools

Architectural and Sporting Equipment: Decorative panels, custom bike parts, golf heads

5. Challenges and Considerations

High Reflectivity: Titanium reflects infrared laser light; fiber lasers with optimized wavelengths mitigate this issue.

Thermal Conductivity: Titanium’s high thermal conductivity requires precise power modulation to avoid edge burning.

Gas Control: Inert gases like nitrogen and argon prevent oxidation and maintain edge integrity during cutting.

Machine Power: Cutting thicker plates (>10 mm) requires high-power laser systems with precise control algorithms.

FAQs – Titanium Laser Cutting

Can titanium be laser cut without losing its mechanical properties?

Yes. When done correctly with optimized parameters, laser cutting preserves titanium’s strength and corrosion resistance.

What types of lasers are used to cut titanium?

Fiber lasers are preferred due to higher absorption rates in titanium. CO₂ lasers may be used with proper gas shielding.

What thickness of titanium can be laser cut?

Typically up to 20 mm depending on laser power, though most applications involve 0.1 mm to 10 mm sheets.

Does laser cutting work for titanium alloys like Grade 5 (Ti-6Al-4V)?

Yes. Ti Time Company supports cutting across all commercial grades, including Grade 2 and Grade 5 titanium.

Do you offer both material supply and laser cutting as a package?

Absolutely. Ti Time Company offers one-stop solutions—from titanium stock supply to CNC laser cutting and custom fabrication.

Titanium laser cutting delivers the ideal balance of precision, speed, and material preservation—enabling the production of strong, corrosion-resistant titanium parts with exceptional accuracy. Whether you’re developing aerospace components or surgical tools, laser cutting ensures the highest levels of quality and efficiency.

Ti Time Company combines titanium material expertise with advanced laser cutting capabilities, offering end-to-end support for manufacturers and engineers seeking premium-quality titanium solutions.