Elevating Flight: The Ultimate Guide to Titanium Materials for Gyrocopter Frames

In the world of rotorcraft aviation, the margin for error is non-existent. Engineers and pilots increasingly turn to a Titanium materials Gyrocopter Frame to achieve the perfect balance of lightweight agility and structural invincibility. Unlike traditional 4130 steel or aluminum, titanium offers a unique set of properties that withstand the high-cycle vibration inherent in gyrocopters.

As a premier supplier, Ti Time Company specializes in the customized manufacturing of aerospace-grade titanium components. Whether you are retrofitting a mast or designing a complete fuselage from scratch, our expertise ensures your aircraft meets rigorous ASTM and AMS safety standards.

II. Why Choose a Titanium Materials Gyrocopter Frame?

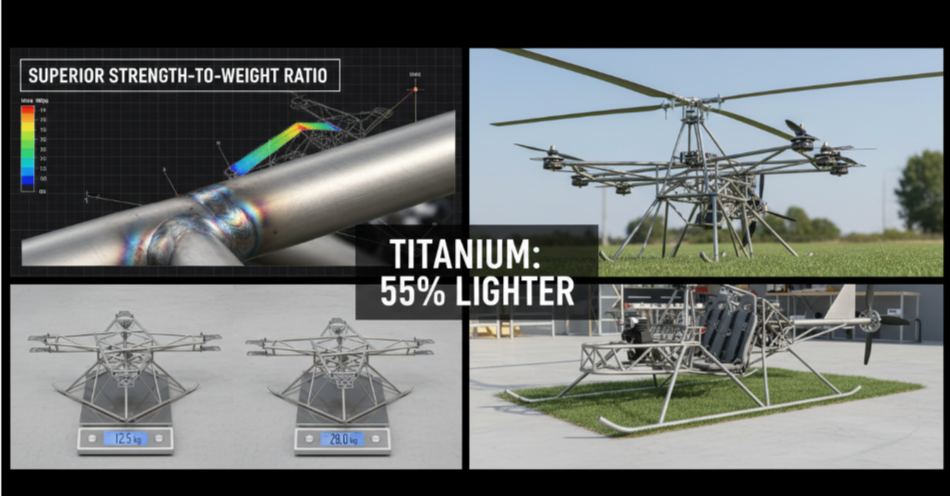

The shift toward Titanium materials Gyrocopter Frame designs is driven by physics. Specifically, Grade 5 Titanium (Ti-6Al-4V) offers a strength-to-weight ratio that far exceeds standard aviation aluminum.

Superior Fatigue Resistance: Gyrocopters endure constant vibration. Titanium’s high fatigue limit makes it the ideal choice for masts and rotor heads, preventing the microscopic cracking that can plague aluminum over time.

Corrosion Immunity: For pilots flying in “outback” conditions, near salt water, or off rough strips, titanium requires no paint and will not rust, ensuring a long-life airframe with minimal maintenance.

Crashworthiness: Titanium possesses a unique “springy” quality (low Young’s modulus relative to steel), allowing the frame to absorb significant energy during hard landings without permanent deformation.

III. Design and Fabrication: Bolted vs. Welded

Working with titanium requires a different approach than steel. At Ti Time Company, we guide our clients through the complexities of fabrication to ensure structural integrity.

The Welding Challenge: Welding titanium demands a sterile environment and 100% argon shielding to effectively prevent embrittlement. High-quality welded frames often require post-weld heat treatment in controlled ovens to relieve stress.

The Bolted Advantage: To mitigate heat-affected zones, many successful designs use a bolted configuration. By using Grade 5 titanium plates and crush tubes, we can create a modular, repairable frame that eliminates the risk of weld-cracking around the mast.

Hybrid Solutions: We often recommend a hybrid approach—using a titanium box-section for the main fuselage and mast, while utilizing composite carbon fiber for fairings and high-strength aluminum for landing gear suspension.

IV. Critical Titanium Components for Gyros

Beyond the main Titanium materials Gyrocopter Frame, Ti Time Company supplies specific high-load components essential for flight safety:

Rotor Head Components: The most stressed part of the aircraft. Titanium ensures reliability under immense centrifugal force.

Hub Bar Plates: Utilizing Ti-6Al-4V to prevent fatigue failure in the rotor system.

Control Rods: Providing stiff, responsive handling without the weight penalty of steel.

V. FAQ: Expert Insights on Titanium Gyrocopters

Q1: Is a Titanium materials Gyrocopter Frame lighter than an aluminum one? A: While titanium is denser than aluminum, its strength is so much higher that you can use less material to achieve the same load-bearing capacity. This results in a frame that is comparable in weight but significantly stronger and more durable.

Q2: Can I weld titanium for my DIY gyrocopter frame in a home shop? A: It is generally not recommended unless you have specialized TIG equipment and purge chambers. Titanium readily absorbs oxygen and hydrogen at high temperatures, which makes welds brittle. Ti Time Company recommends bolted assemblies or factory-welded components for safety.

Q3: What is the cost difference between 4130 Steel and Titanium? A: Titanium raw material and processing costs are significantly higher than steel. However, the investment pays off in the longevity of the airframe, lack of corrosion, and resale value of the aircraft.

Q4: Does Ti Time Company offer Grade 5 (Ti-6Al-4V) for gyrocopter masts? A: Yes. We supply seamless tubes and solid bars in Ti-6Al-4V, which is the preferred alloy for masts due to its exceptional yield strength and resistance to bending loads.

Q5: Can you manufacture custom landing gear legs? A: Yes. While many use aluminum for gear, we can produce customized titanium spring gear legs for pilots requiring maximum durability for rough-field operations.

VI. Ti Time Company: Your Trusted Partner for Advanced Materials

Ti Time Company is a leading manufacturer and supplier specializing in titanium, tungsten, molybdenum, tantalum, niobium, zirconium, anodes, and composite materials. With decades of experience, we are known for delivering high-quality products and exceptional customer service.

Our offerings include plates, rods, tubes, foils, wires, screws, capillary tubes, targets, custom parts, forgings, and alloys. Operating under the ISO9001 quality system, our products meet ASTM, ASME, AMS, JIS, DIN, and MIL standards, and are exported to countries such as the US, Japan, Germany, and South Korea.

Whether you need a titanium sputtering target for high-tech coating or a rugged Titanium materials Gyrocopter Frame for your next aircraft, Ti Time is your partner in precision.