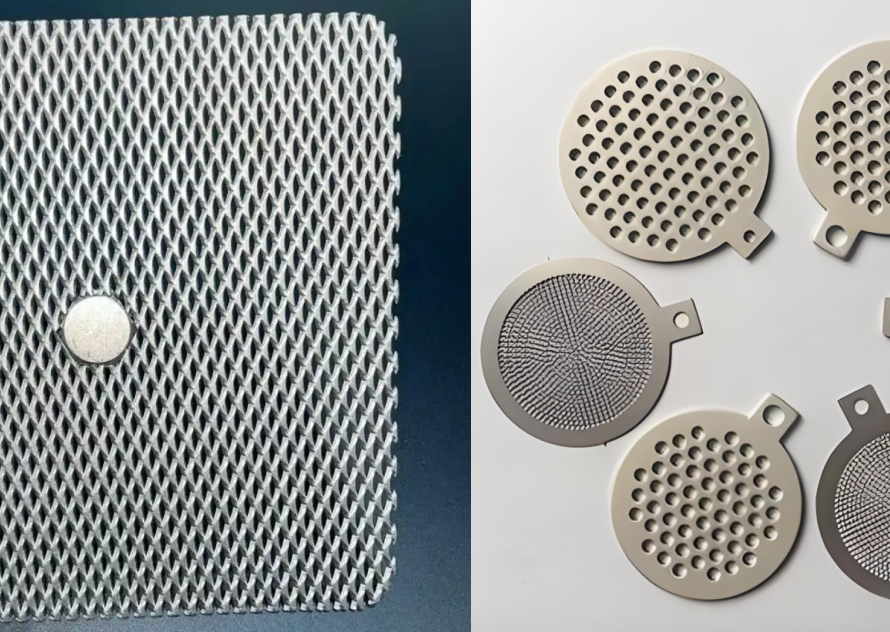

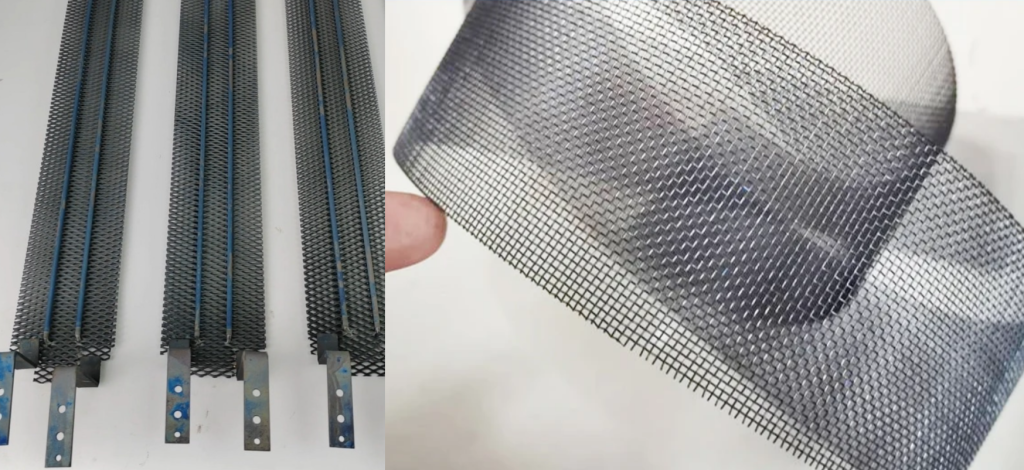

Titanium mesh electrodes leverage the exceptional corrosion resistance, lightweight properties, and mechanical strength of titanium as a substrate, enhanced with specialized catalytic coatings. These coatings, typically involving precious metals like Platinum, Iridium, Ruthenium, and Tantalum oxides, impart specific electrochemical properties, making these electrodes highly efficient, durable, and cost-effective solutions for a wide range of industrial processes including electroplating, water treatment, chemical synthesis, and cathodic protection.

Types of Titanium Mesh Electrodes:

Platinum Coated Titanium Mesh Electrode (Pt/Ti):

This type features a layer of platinum electrodeposited or thermally decomposed onto the titanium mesh substrate. It serves as a highly effective and more economical alternative compared to using solid platinum electrodes. The platinum coating provides excellent catalytic activity for various reactions and maintains inertness, preventing interference with the electrochemical process.

Applications: Primarily used as an anode or cathode, particularly as a counter electrode in electrochemical cells. It excels in electrodeposition (plating) processes and is suitable for systems where organic or inorganic fouling might occur. Common in laboratory settings and specialized industrial applications.

Specifications: Typically utilizes a GR1 titanium base with platinum coating thickness ranging from 760 to 1500 nm (0.76 to 1.5 microns), though customizable thicknesses and mesh sizes are available.

Iridium-Tantalum Coated Titanium Mesh Electrode (Ir-Ta/Ti):

Coated with a mixed metal oxide (MMO) layer primarily composed of iridium and tantalum oxides. This combination is renowned for its exceptional corrosion resistance, particularly in highly acidic environments, and its low overpotential specifically for the oxygen evolution reaction (OER).

Applications: Widely favored in demanding industrial processes such as copper foil production (anode for electrolysis), electroplating (especially acid copper plating), robust cathodic protection systems (impressed current cathodic protection – ICCP), and certain types of organic electrosynthesis.

Specifications: Characterized by superior electrochemical stability and a significantly longer operational lifespan compared to conventional electrodes like graphite or lead alloys, especially under high current densities or in aggressive media.

Ruthenium-Iridium Oxides Coated Titanium Mesh Electrode (Ru-Ir/Ti):

This electrode utilizes a mixed metal oxide coating containing both ruthenium and iridium oxides. Ruthenium oxide is highly catalytic for the chlorine evolution reaction (CER), while iridium oxide enhances stability and longevity. This combination results in high conductivity and stability, particularly in chloride-containing solutions. Often referred to generally as Dimensionally Stable Anodes (DSA® – a trade name, but the technology is widespread).

Applications: Its primary application is in the chlor-alkali industry for producing chlorine gas and caustic soda. It is also highly effective in industrial wastewater treatment (e.g., electrochlorination for disinfection, electrochemical oxidation of pollutants) and metal recovery processes (electrowinning from chloride solutions).

Specifications: Manufactured using high-tensile titanium mesh and a carefully controlled coating process to ensure durability and low consumption rates (long service life) even under strenuous industrial conditions.

General Characteristics and Advantages:

- Substrate: Titanium provides a lightweight, strong, and fundamentally corrosion-resistant base.

- Coatings: Tailored coatings (Pt, Ir-Ta MMO, Ru-Ir MMO) enhance catalytic activity for specific reactions (OER, CER, HER) and provide exceptional resistance to chemical attack.

- Versatility: Suitable for a broad spectrum of electrochemical applications.

- Durability: Offer long service life and maintain dimensional stability under operation.

- Cost-Effectiveness: Provide performance comparable or superior to noble metal electrodes at a lower cost, and significantly outperform older technologies like graphite or lead alloys in terms of lifespan and efficiency.

- Efficiency: Often exhibit lower overpotentials for desired reactions, reducing energy consumption.

What are the main applications of platinum-coated titanium mesh electrodes?

Based on the text, the main applications are serving as a counter electrode in various electrochemical cells, particularly within electrodeposition processes (like electroplating), and in systems that are prone to contamination or fouling by organic or inorganic deposits.

How does the platinum coating improve the performance of titanium mesh electrodes?

The platinum coating improves performance primarily by providing catalytic properties essential for facilitating specific electrochemical reactions efficiently. Additionally, it ensures the electrode surface remains inert (chemically non-reactive) under the reaction conditions, preventing unwanted side reactions or degradation. This makes the titanium base usable in applications requiring platinum’s catalytic activity without the high cost of a solid platinum electrode.

Are there any specific industries that prefer iridium-tantalum coated titanium mesh electrodes?

Yes, specific industries that prefer iridium-tantalum coated titanium mesh electrodes due to their strong corrosion resistance (especially in acids) and low oxygen evolution overpotential include:

- Copper foil production

- Electroplating (particularly acidic processes)

- Cathodic protection (especially impressed current systems)

- Organic synthesis (certain electrosynthesis reactions)