The term “titanium oxide electrode” often surfaces when discussing electrochemical applications, leveraging titanium’s excellent corrosion resistance and mechanical strength. However, a crucial point is often missed: the naturally occurring titanium dioxide (TiO₂) layer that forms on pure titanium is actually an electrical insulator, making it unsuitable on its own for most electrode functions requiring conductivity.

So, when people search for or discuss “titanium oxide electrodes,” they are typically referring to a more sophisticated solution: titanium metal used as a stable substrate, coated with specific, conductive metal oxides. These coatings provide the necessary electrocatalytic activity and conductivity, while the titanium base offers longevity and structural integrity.

Let’s delve into why pure TiO₂ falls short and explore the effective coated titanium electrodes used widely across industries.

Why Isn't Native Titanium Dioxide Used as an Electrode?

When titanium is exposed to air or used in electrolysis, it spontaneously forms a thin, tightly adherent passive layer of titanium dioxide (TiO₂). While this layer is responsible for titanium’s exceptional corrosion resistance, it’s fundamentally non-conductive. This lack of electrical conductivity prevents efficient electron transfer, which is essential for any electrode’s function in an electrochemical cell. Therefore, a “pure” titanium oxide electrode derived solely from this passive layer isn’t practical for applications demanding current flow.

The Solution: Conductive Coatings on Titanium Substrates

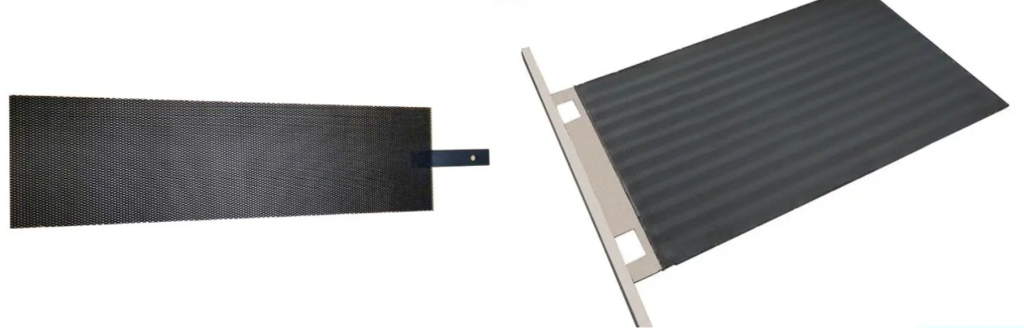

To overcome the insulating nature of TiO₂, manufacturers use titanium metal (often as plates, mesh, or rods) as a robust base material and apply specialized, electrically conductive coatings. These coatings are frequently composed of precious metal oxides or other specific metal oxides known for their electrocatalytic properties and stability in harsh environments.

This approach combines the best of both worlds: the superior corrosion resistance and strength of the titanium substrate and the required electrochemical performance of the surface coating.

Popular Types of Coated Titanium Electrodes (Often Referred to as Titanium Oxide Electrodes

Several types of coated titanium electrodes are available, each tailored for specific applications:

1. Mixed Metal Oxide (MMO) Electrodes

- Description: These are perhaps the most common type. They feature a titanium substrate coated with a mixture of conductive metal oxides, typically including Ruthenium Dioxide (RuO₂) and/or Iridium Dioxide (IrO₂).

- Features: Excellent electrochemical stability, high catalytic activity, long service life, and resistance to various chemical environments.

- Applications: Widely used in chlor-alkali production, water treatment (disinfection, purification), cathodic protection systems, swimming pool chlorinators, and electroplating.

- Consideration: The use of precious metals (Ru, Ir) makes them more expensive than uncoated titanium or some alternatives.

2. Iridium-Tantalum (Ir-Ta) Coated Titanium Electrodes

- Description: These electrodes utilize a coating blend of Iridium Oxide (IrO₂) and Tantalum Oxide (Ta₂O₅) on a titanium base, often in mesh form for better flow dynamics.

- Features: Exceptional stability in highly acidic solutions, low overpotential for oxygen evolution (OER), high physical stability, and excellent corrosion resistance.

- Applications: Ideal for demanding industrial processes like electrowinning metals from acidic solutions, copper foil production, certain types of organic electrosynthesis, and harsh water treatment scenarios.

- Consideration: Often a premium option due to the specific precious metal (Ir) and refractory metal (Ta) oxides used.

3. Lead Dioxide (PbO₂) Coated Titanium Anodes

- Description: This type uses a layer of Lead Dioxide (PbO₂) applied over the titanium substrate.

- Features: Provides a conductive and catalytically active surface without relying on precious metals. Effective for specific oxidation reactions.

- Applications: Used in electrowinning, hydrometallurgy, and particularly effective in wastewater treatment for degrading recalcitrant organic pollutants and perchlorate removal.

- Consideration: PbO₂ coatings might have limitations in certain chemical environments or lower overall lifespan compared to MMO coatings, and environmental considerations regarding lead exist.

4. Ruthenium-Iridium (Ru-Ir) Coated Titanium Electrodes

- Description: A specific formulation within the MMO family, explicitly highlighting Ruthenium and Iridium oxides in the coating.

- Features: Optimized for high efficiency in chlorine evolution reactions, excellent conductivity, and good durability in chloride-containing environments.

- Applications: Very common in salt chlorine generators for swimming pools and spas, brine electrolysis, and some specialized water treatment systems.

- Consideration: Cost is influenced by the loading of precious metals.

Choosing the Right Coated Titanium Electrode

Selecting the appropriate “titanium oxide electrode” (coated titanium electrode) depends heavily on the target application:

- Electrolyte Composition: Is it acidic, alkaline, or neutral? Does it contain chlorides, sulfates, or other specific ions? (e.g., Ir-Ta for acids, Ru-Ir for chlorides).

- Desired Reaction: Are you evolving chlorine, oxygen, or performing specific oxidation/reduction? (Different coatings have different catalytic selectivities).

- Current Density & Efficiency: What are the operational requirements?

- Budget: Precious metal coatings (MMO, Ir-Ta, Ru-Ir) are generally more expensive but offer longer life than options like PbO₂.

Custom Titanium Oxide Electrode Solutions with Ti Time

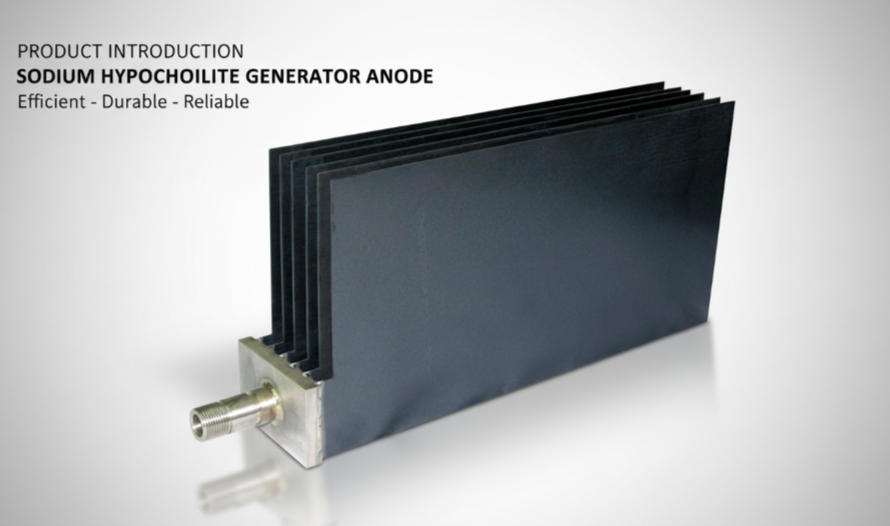

Finding the perfect off-the-shelf electrode isn’t always possible. Specific industrial processes or novel applications often require tailored solutions. Ti Time is a leading manufacturer and supplier specializing in titanium and titanium-based products, including the custom production of various coated titanium electrodes – often referred to under the umbrella term “titanium oxide electrodes.”

Whether you need MMO, Ir-Ta, PbO₂, or other specialized coated titanium anodes or cathodes, Ti Time has the expertise to manufacture electrodes that meet your precise requirements for dimensions, coating composition, substrate form (plate, mesh, tube, wire), and performance characteristics. They work closely with clients to understand their unique electrochemical needs and deliver high-quality, customized electrode solutions.