Ti Time: An Outstanding Manufacturer and Supplier of Metal Materials

Titanium sheet metal is widely valued for its exceptional strength-to-weight ratio, corrosion resistance, and long-term stability, making it indispensable across aerospace, chemical processing, medical devices, water treatment, and advanced electrochemical systems. Selecting a reliable manufacturer is critical, as the performance of titanium—density ~4.5 g/cm³, tensile strength, and corrosion resistance—depends heavily on material purity, processing control, and certification compliance.

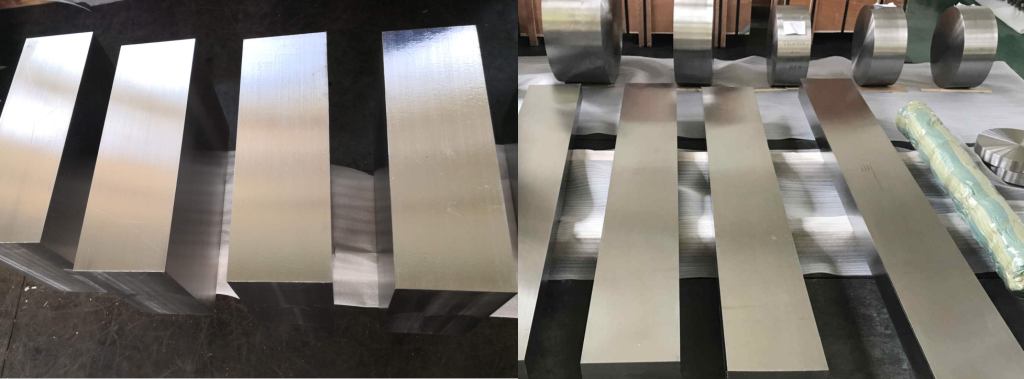

Ti Time stands out as an outstanding manufacturer and global supplier of titanium sheet metal and titanium-based components, offering consistent quality, flexible customization, and strong technical expertise for demanding applications.

Titanium Sheet Metal from Ti Time

Ti Time supplies a full range of titanium sheet and plate products manufactured in accordance with ASTM B265, ASME, and ISO standards, ensuring traceability and performance consistency.

Available Grades

Commercially Pure Titanium (Gr1 / Gr2)

Excellent corrosion resistance, high formability, ideal for chemical equipment and electrolysis applications.Ti-6Al-4V (Grade 5)

High strength and fatigue resistance, suitable for aerospace, medical, and high-load industrial components.Other titanium alloys available upon request for specialized environments.

Thickness & Dimensions

Standard thickness range: 0.016 in (0.4 mm) to 0.5 in (12.7 mm)

Custom cutting, rolling, and surface finishing supported

Tight thickness tolerance and flatness control for precision assemblies

Key Considerations When Purchasing Titanium Sheet Metal

When sourcing titanium sheet metal, Ti Time emphasizes the following professional criteria:

Material Certification

Full Mill Test Certificates (MTC), chemical composition reports, and mechanical property verification.Process Control

Controlled rolling, annealing, and surface treatment to ensure stable microstructure and corrosion resistance.Cost Efficiency at Scale

Competitive pricing for bulk orders while maintaining consistent quality.Logistics & Export Experience

Global shipping with professional packaging to prevent surface damage or deformation.

Typical pricing ranges USD 15–100 per pound, depending on grade, thickness, and order volume. Custom cutting minimizes material waste, improving overall project economics.

Titanium for Electrolyzed Water Anodes

One of Ti Time’s core technical strengths lies in titanium substrates for electrolyzed water anodes, a critical component in electrolysis systems producing acidic, alkaline, or functional water.

Base Material

High-purity Titanium Gr1 / Gr2

Excellent mechanical strength (>240 MPa) and corrosion resistance

Stable passive oxide layer for long-term electrochemical operation

Advanced Coatings

Ti Time provides precision coating solutions tailored to electrochemical performance needs:

| Coating Type | Catalytic Advantages | Typical Lifespan | Key Applications |

|---|---|---|---|

| Platinum (Pt) | Extremely low overpotential, high OER activity | 3–5 years | Water ionizers, hydrogen-rich water |

| Iridium (Ir) | Superior oxidation resistance | 4–6 years | Sterilization, wastewater treatment |

| Ru-Ir MMO | High efficiency for chlorine & oxygen evolution | 5–7 years | Disinfection systems |

| Ir-Ta MMO | Balanced durability and cost | 4–6 years | General water treatment |

MMO coatings typically reduce energy consumption by 15–20% compared with uncoated electrodes, with coating thickness controlled between 1–5 µm for optimal adhesion and longevity.

Electrochemical Performance & Reaction Control

Ti Time anodes are engineered for high-efficiency electrolysis:

Current density: 1,000–5,000 A/m² (up to 8,000 A/m² for Ru-Ir systems)

Current efficiency: >90% in optimized conditions

Operating temperature: up to 60 °C

pH tolerance: 0–11

Optimized designs minimize side reactions, control gas evolution, and ensure stable ORP and pH output in continuous-use systems.

Applications Across Industries

Ti Time titanium materials and anodes are widely used in:

Electrolyzed water generators (acidic & alkaline)

Industrial and municipal water treatment

Food processing and sanitation systems

Medical and wound-care devices

Agricultural disinfection and spraying equipment

Hydrogen-rich water devices and household ionizers

Their reliability supports both industrial-scale systems and compact consumer devices requiring long service life and stable output.

Ti Time: Expertise, Authority, and Trust

With 15+ years of experience in Titanium Valley, Ti Time integrates material science, electrochemical engineering, and manufacturing excellence.

Why Choose Ti Time?

ISO & SGS certified production systems

Low MOQ with rapid prototyping capability

Custom shapes, sizes, and coating formulations

Proven export experience across global markets

Continuous R&D, including nano-enhanced MMO coatings aimed at reducing precious metal usage by up to 20%

Ti Time’s commitment to quality, innovation, and transparency ensures dependable performance in critical applications.

Whether sourcing titanium sheet metal or high-performance electrolyzed water anodes, Ti Time represents a reliable and authoritative partner. Through rigorous quality control, advanced coating technologies, and flexible customization, Ti Time delivers metal material solutions that meet the highest industrial and electrochemical standards.

Ti Time — Precision Titanium Materials for Advanced Engineering Applications.