What is a Titanium Sputtering Target?

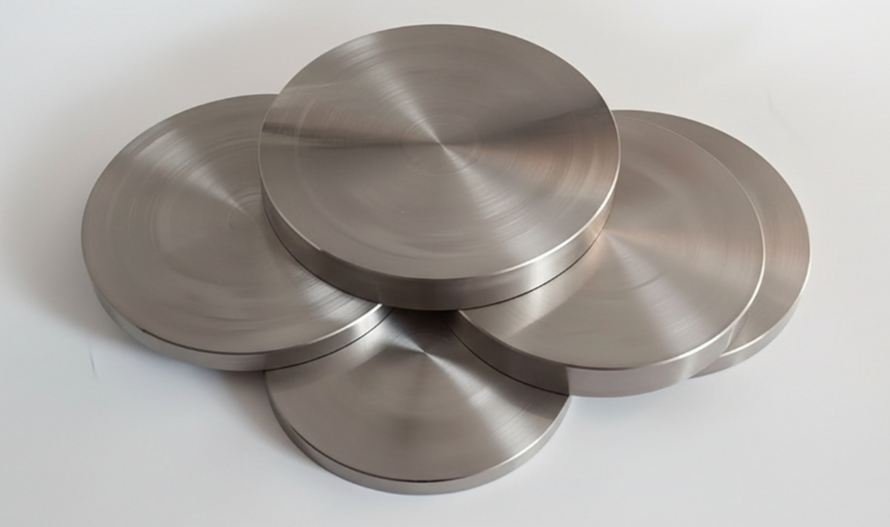

A Titanium Sputtering Target is a high-purity solid titanium form—typically machined into circular discs, rectangular plates, or rotatable tubes—used as the cathode in sputtering systems.

The process is precise: within a vacuum chamber, energetic ions (usually Argon) bombard the target surface. This collision ejects (sputters) Titanium atoms, which travel through the vacuum and condense onto a substrate (such as silicon wafers, glass, or quartz). The result is a thin, uniform Ti film essential for modern technology.

The Role of Purity and Metallurgy

For industrial applications, “standard” titanium isn’t enough. Ti Time Company specializes in refining titanium to meet specific metallurgical standards:

Purity Levels: Ranging from 99.2% (Industrial Grade) for decorative coatings to 99.995% (4N5) for microelectronics. High purity is crucial to prevent conductive failures in semiconductor circuits.

Microstructure: A high-quality target features a fine, uniform grain size. This ensures that the erosion rate remains consistent across the target surface, preventing “spitting” (particle generation) and ensuring the film thickness is uniform across the wafer.

Applications: Where Customization Matters

As a specialized Titanium Sputtering Target supplier, Ti Time Company understands that one size does not fit all. We provide custom manufacturing to suit diverse industry needs:

Semiconductors: Titanium is used as a critical adhesion layer or barrier layer in integrated circuits.

Optics: Ti films are used for their specific refractive indices in multi-layer optical stacks.

Decorative & Wear: Used in watches and tools, often reacted with Nitrogen to form Titanium Nitride (TiN), creating a hard, gold-colored coating.

Energy: Used in solar photovoltaics for conductive back-layers.

Why Partner with Ti Time Company?

Sourcing targets requires confidence in your supply chain. Ti Time Company bridges the gap between raw material extraction and precision finishing.

Custom Dimensions: We manufacture targets to fit any system, from small 2-inch R&D guns to large-scale 8-inch industrial magnetrons. Thicknesses typically range from 0.125” to 0.25”, but fully bespoke geometries are available.

Bonding Services: To ensure efficient cooling and structural integrity, we offer Indium or Elastomer bonding to copper backing plates, essential for high-power sputtering.

Traceability: Every target comes with a Certificate of Analysis (COA), verifying purity and trace element content.

FAQ: Expert Answers on Titanium Targets

1. What is the difference between Grade 2 and 5N purity Titanium targets? Grade 2 (approx. 99.2% Ti) is generally used for industrial wear coatings or decorative applications where cost is a factor. 5N (99.999%) purity is strictly for semiconductor and high-end optical applications where even microscopic impurities can cause device failure.

2. Should I use a Monolithic or Bonded Titanium target? If your target is thick and mechanically strong, a monolithic (solid) construction is fine. However, for thinner targets or to improve cooling efficiency during high-power usage, we recommend bonding the Titanium to a Copper backing plate.

3. Can Ti Time Company produce rotatable Titanium targets? Yes. While planar (disc) targets are common, we also manufacture rotatable (tubular) Titanium Sputtering Targets. These offer higher material utilization rates for large-area coating lines, such as architectural glass manufacturing.

4. How does grain size affect my sputtering process? Large or uneven grain sizes in the metal can lead to varying erosion rates, which results in uneven film thickness on your product. Ti Time Company utilizes specialized thermo-mechanical processing to ensure a fine, uniform grain structure for consistent deposition.

5. What is the typical lead time for custom targets? Standard sizes (e.g., 3-inch, 4-inch discs) are often in stock. For custom manufacturing of unique geometries or specific purities, production typically takes 2–3 weeks depending on the complexity of the backing plate and bonding requirements.