Titanium Sputtering Target Price Guide: Sourcing High-Purity Materials from a Trusted Supplier

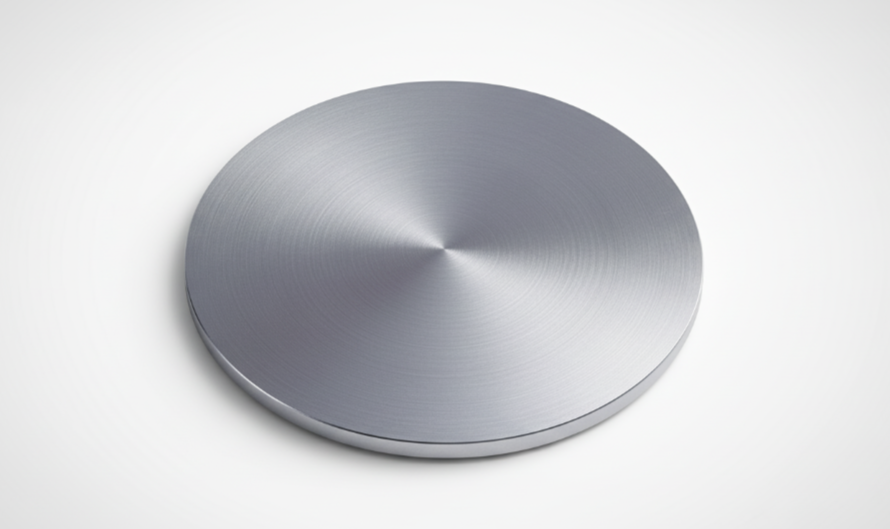

In the precise world of Physical Vapor Deposition (PVD), the quality of your source material dictates the performance of your final thin film. Whether for semiconductor logic gates, optical coatings, or decorative finishes, selecting the right titanium sputtering target is a critical decision.

As a globally recognized titanium sputtering target supplier, Ti Time Company understands that engineers and procurement managers need more than just a product; they need a balance of high purity, structural integrity, and competitive pricing. We provide customized manufacturing solutions that cater to both small-scale laboratory research and large-scale industrial coating lines.

II. Understanding the Titanium Sputtering Target Price Landscape

One of the most common questions we receive is regarding the titanium sputtering target price. The cost is not fixed; it fluctuates based on manufacturing complexity, purity levels, and market demand for raw titanium sponge.

When budgeting for your PVD needs, consider these typical price ranges based on current market data:

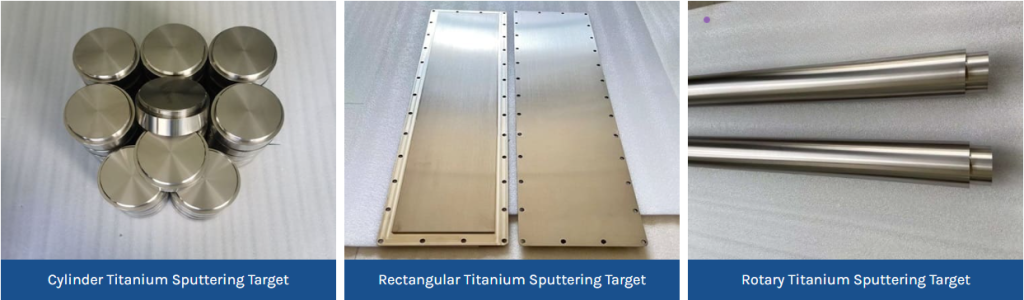

Small Lab Planar Targets: For R&D (1–3 inch diameter, ≥99.9% purity), prices typically range from $100 to $500 USD per piece.

High-Purity or Larger Planar Targets: Semiconductor-grade materials (99.995%–99.999%) or larger dimensions generally cost $180 to $500+ USD per piece.

Rotary / Tubular Targets: Designed for large-area coating, these targets (including special alloys like TiAl) range from $800 up to $2,000+ USD per piece.

Bulk Industrial Pricing: Some suppliers quote by weight for basic specifications, roughly $20–$100 USD per kg, dependent on bonding and order volume.

Ti Time Company helps you navigate these costs by offering transparent pricing models and optimizing production methods to reduce waste, ensuring you get the best value for your specific application.

III. The Science Behind the Sputter: Why Quality Matters

Titanium sputtering is a violent process at the atomic level. High-energy ions bombard the target, ejecting atoms to form a coating. If the target has internal defects, the results can be catastrophic for the end product.

At Ti Time Company, we focus on three critical quality metrics:

Purity: We offer grades from 99.5% (Industrial) to 99.999% (Semiconductor). Higher purity reduces the risk of particle generation and electrical shorts in microelectronics.

Grain Structure: Our targets undergo specialized thermomechanical processing to achieve a fine, uniform grain size. This ensures consistent erosion rates and uniform film thickness.

Density: We achieve near-theoretical density to prevent “arcing” and nodule growth during the titanium sputtering process.

IV. Customized Manufacturing for Global Industries

Off-the-shelf solutions do not fit every vacuum chamber. As a premier supplier, Ti Time Company excels in customized production. Whether you require a monolithic design or a target bonded to a copper backing plate for better cooling, we manufacture to your exact drawings.

We operate under the ISO9001 quality system, ensuring our products meet ASTM, ASME, and AMS standards. Our diverse portfolio extends beyond titanium to include tungsten, molybdenum, tantalum, and zirconium, exported to demanding markets in the US, Japan, Germany, and South Korea.

V. FAQ: Expert Answers on Titanium Sputtering Targets

Q1: What are the primary factors that influence the titanium sputtering target price? A: The price is driven by purity (adding a “9” to purity exponentially increases refining costs), geometry (rotary targets require more machining), and bonding requirements (indium vs. elastomer bonding).

Q2: How do I choose between a planar and a rotary titanium sputtering target? A: Planar targets are ideal for R&D and smaller batches. Rotary targets offer much higher material utilization (up to 80% vs. 30% for planar) and are the standard for large-scale, continuous architectural glass or web coating lines.

Q3: What is the difference between Grade 2 Titanium and 5N (99.999%) Titanium for sputtering? A: Grade 2 is commercially pure (approx. 99.2%) and suitable for decorative or corrosion-resistant coatings. 5N Titanium is ultra-pure, used in semiconductor applications where even trace amounts of iron or oxygen could ruin a microchip’s performance.

Q4: Can Ti Time Company supply alloy targets like Titanium-Aluminum (TiAl)? A: Yes. TiAl is a popular material for hard coatings on cutting tools. We use powder metallurgy to ensure a homogeneous mix of Titanium and Aluminum, preventing “spitting” during the deposition process.

Q5: How does Ti Time ensure the quality of its targets? A: We provide a comprehensive COA (Certificate of Analysis) with every batch, detailing the chemical composition (ICP-OES analysis) and gas content. We also perform Ultrasonic Testing (UT) to guarantee the bonding integrity between the target and the backing plate.

VI. Ti Time Company: Your Trusted Partner for Advanced Materials

Ti Time Company is a leading manufacturer and supplier specializing in titanium, tungsten, molybdenum, tantalum, niobium, zirconium, anodes, and composite materials. With decades of experience, we are known for delivering high-quality products and exceptional customer service.

Our offerings include plates, rods, tubes, foils, wires, screws, capillary tubes, targets, custom parts, forgings, and alloys. Operating under the ISO9001 quality system, our products meet ASTM, ASME, AMS, JIS, DIN, and MIL standards, and are exported to countries such as the US, Japan, Germany, and South Korea.