TITIME Offers Customized Titanium Raw Materials for Welding Electrodes – Boosting Quality and Efficiency

April 2025 — Leading titanium materials provider TITIME has officially launched a customized titanium raw material service tailored for Titanium Welding Electrode manufacturers and end-users. The service ensures long-term stable supply, flexible specifications, and expert technical support—empowering industries to elevate their welding performance.

Why Choose Titanium Welding Electrodes?

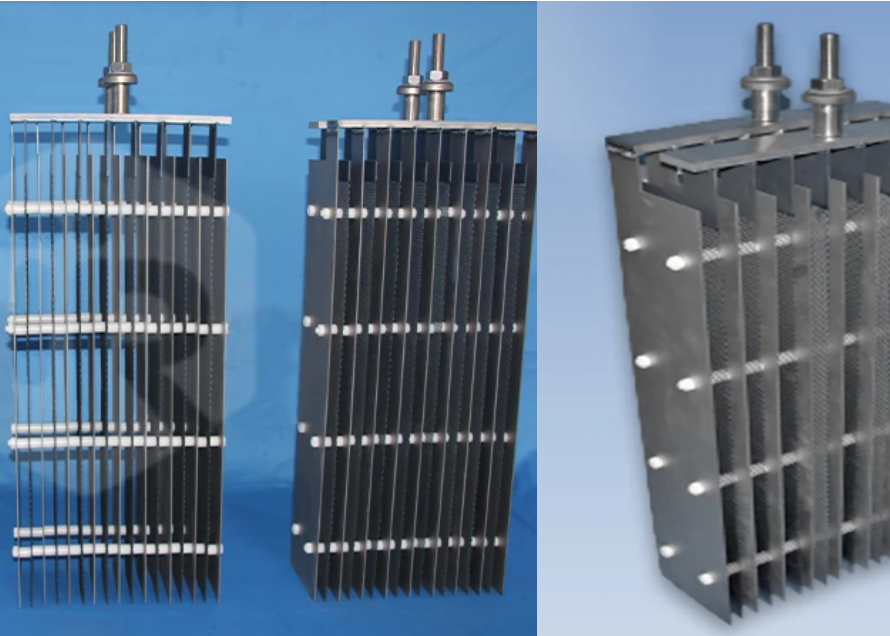

Titanium welding electrodes are vital in industries like aerospace, medical equipment, and marine engineering due to titanium’s excellent strength-to-weight ratio and corrosion resistance.

However, high-quality titanium welding demands electrode materials with exceptional purity, process adaptability, and reliable supply. TITIME leverages its extensive experience in titanium production to deliver high-performance titanium alloy materials that meet diverse welding process requirements.

Titanium Supply for Various Welding Techniques

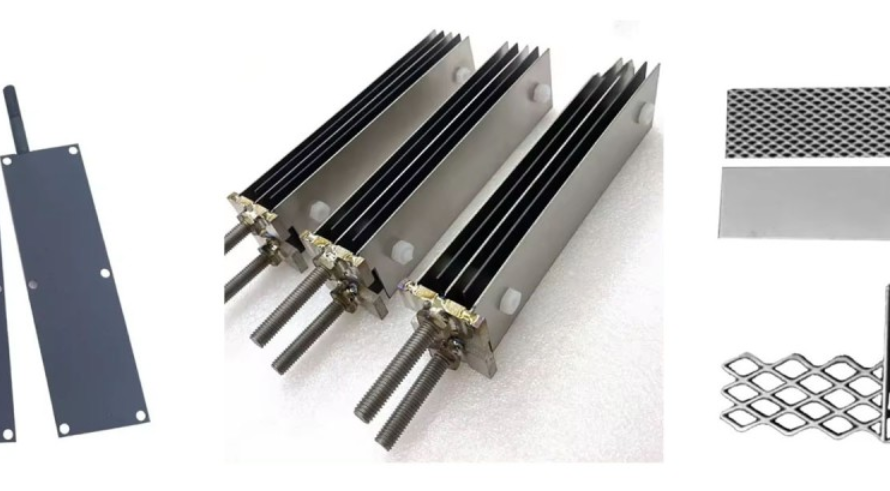

1. TIG Welding (Tungsten Inert Gas)

Uses non-consumable tungsten electrodes (e.g., pure tungsten, lanthanated, ceriated)

TITIME provides billet and wire materials adapted for TIG applications

Recommended: Flat-tipped tungsten electrodes to reduce inclusion and ensure weld strength

2. MIG Welding (Metal Inert Gas)

Suitable for welding thicker titanium sections

TITIME offers titanium wire and sheet materials compatible with MIG systems

3. Shielding Gas Best Practice

Use 99.999% high-purity argon for inert shielding during welding

Combined with high-grade titanium to prevent contamination and ensure weld integrity

TITIME’s Advantages in Titanium Raw Material Supply

✅ High Material Purity: Titanium billets, wires, and sheets with >99.9% purity

✅ Custom & Batch Flexibility: Specifications tailored to your welding equipment and process

✅ Technical Support: Expert advice on material selection and electrode development

✅ Global Logistics: Efficient delivery and supply chain coordination

✅ Industry-Grade Certification: Trusted by aerospace, energy, and medical sectors

Behind High-Quality Welding Lies Better Raw Materials – From TITIME

“We understand that the quality of a weld starts with the material behind the electrode,” said TITIME’s R&D Director. “As Titanium Welding Electrodes play a critical role in performance, our mission is to deliver the most reliable material foundation so our clients can focus on precision welding.”

📞 Need titanium materials for electrode manufacturing? Contact us for samples and pricing.

🌐 Website: www.titimecn.com

📩 Email: info@titimecn.com