Welding titanium to steel presents one of the most significant challenges in metallurgical engineering due to the formation of brittle intermetallic compounds like TiFe and TiFe₂. These compounds severely weaken the weld joint, making direct fusion welding between titanium and steel impractical in most industrial settings.

As an experienced titanium supplier and materials solutions provider, Ti Time Company offers expert guidance, intermediate alloy materials, and technical support for joining titanium to dissimilar metals such as steel—based on proven methods and cutting-edge research.

1. Experience: Specialized in Dissimilar Metal Solutions

With decades of experience in advanced titanium fabrication and welding technologies, Ti Time Company supports manufacturers in aerospace, defense, marine, and petrochemical sectors—where joining titanium to steel is often necessary yet complex.

We supply titanium, buffer metals like zirconium and vanadium, and tailored cladding solutions to ensure functional, durable joints between dissimilar metals.

2. Why Titanium-to-Steel Welding Is Difficult

✦ Brittle Intermetallic Formation

Direct fusion results in TiFe and TiFe₂ phases, which are extremely brittle and prone to cracking.

These intermetallics drastically reduce weld strength and ductility.

✦ Thermal Expansion and Solubility Mismatch

Titanium and steel have different melting points and thermal properties, causing distortion and residual stress in the weld zone.

3. Proven Methods for Welding Titanium to Steel

1. Intermediate Buffer Layers

Vanadium and zirconium can serve as “transition” metals that bond well with both titanium and steel.

A multi-layer weld process is used:

Weld zirconium to titanium

Weld zirconium to steel

This significantly reduces brittle phase formation.

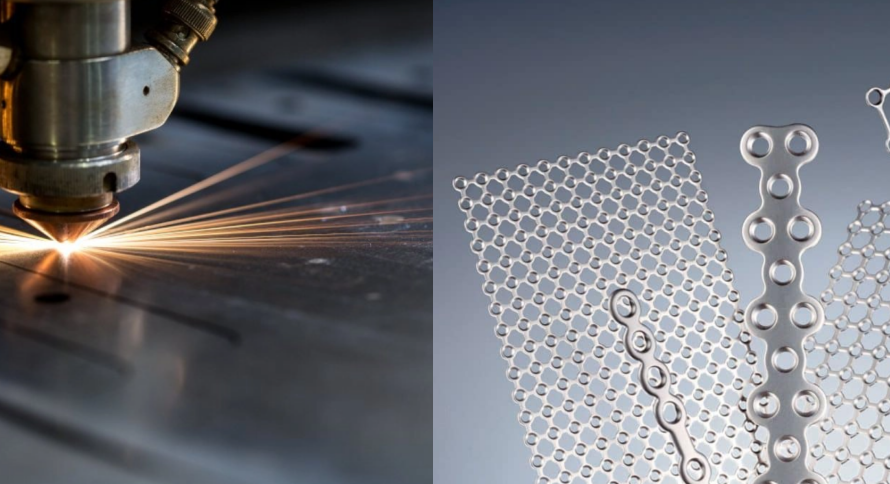

✅ 2. Solid-State Welding Techniques

Friction Welding: Uses pressure and heat from motion, avoiding melting; ideal for titanium rods and tubes.

Diffusion Welding: High heat and pressure under vacuum conditions; used for aerospace and nuclear components.

Explosive Cladding: Industrial-scale solution to bond large titanium and steel plates using shockwaves.

❌ Brazing (Not Recommended)

Poor bond strength due to oxidation above 700°F and difficulty managing the joint environment.

✅ 3. Mechanical Fastening

Bolt or flange systems using machined titanium and steel parts avoid all metallurgical issues and are widely used in industrial systems.

4. Welding Environment Requirements

Titanium must be welded in a fully shielded environment with 100% high-purity argon gas to prevent embrittlement due to oxygen or nitrogen exposure.

Use GTAW (TIG welding) for titanium sections, but only with proper transition metals when joining to steel.

FAQs – Welding Titanium to Steel

Can titanium and steel be directly welded?

No. Direct fusion welding causes brittle intermetallics that lead to cracking and structural failure.

What is the best method to weld titanium to steel?

Use buffer metals (like zirconium or vanadium) or opt for solid-state welding methods like friction welding or explosion bonding.

Why is friction welding effective?

It avoids melting, minimizing intermetallic formation and allowing for stronger dissimilar metal joints.

Is brazing titanium to steel viable?

Generally not recommended. Brazing leads to oxidation and weak joints when joining titanium to steel.

Does Ti Time Company provide buffer metals or cladding services?

Yes. We offer zirconium, vanadium, and other buffer materials, along with custom cladding and welding consultation for titanium-steel integration.