Why Choose Ti Time Company as Your Zirconium Oxide Supplier?

Ti Time Company is a trusted name in advanced material solutions. With extensive experience in titanium electropolishing and zirconium oxide production, we specialize in customized manufacturing tailored to client specifications. Our expertise ensures that every zirconium oxide product meets the highest standards of quality, consistency, and performance.

Experience: Over a decade of proven track record in supplying zirconium oxide for industrial and medical applications.

Expertise: Technical knowledge of zirconia phases, stabilization techniques, and application-specific requirements.

Authoritativeness: Recognized as a global supplier, delivering zirconium oxide to industries such as dental, aerospace, fuel cells, and electronics.

Trustworthiness : Strict quality control, certification, and customer support guarantee reliable and long-term partnerships.

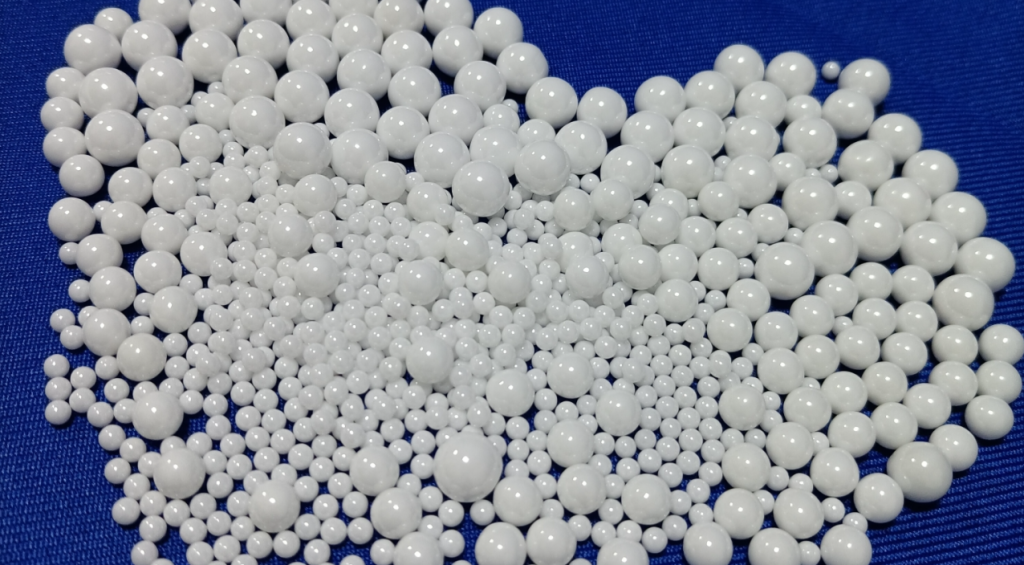

Key Properties of Zirconium Oxide

High melting point (~2700°C) and boiling point (~4300°C)

Exceptional fracture toughness due to transformation toughening

Low thermal conductivity, ideal for thermal barrier coatings

Chemically inert and resistant to most acids

Biocompatible and safe for medical implants

Applications of Zirconium Oxide

Medical & Dental: Crowns, bridges, and implants for long-lasting performance

Electronics & Energy: Advanced ceramic components, fuel cells, and oxygen sensors

Aerospace & Automotive: Thermal barrier coatings, wear-resistant parts

Jewelry: Synthetic gemstones (cubic zirconia)

Industrial Manufacturing: Cutting tools, ceramics, and high-temperature applications

Production Process

Commercial zirconium oxide is produced through thermal dissociation and calcination of zirconium compounds, often derived from zircon sand. Stabilization with oxides such as yttria (Y2O3) ensures phase stability at room temperature, enhancing its mechanical toughness.

FAQs about Zirconium Oxide Supplier – Ti Time Company

What industries commonly use zirconium oxide from Ti Time Company?

Our zirconium oxide is widely used in dental, medical, aerospace, fuel cell, and advanced ceramic industries.

Can Ti Time Company provide customized zirconium oxide products?

Yes, we specialize in customized production, offering zirconium oxide materials tailored to client needs in terms of size, purity, and phase stabilization.

How does Ti Time Company ensure quality control?

We implement rigorous inspection protocols, material certifications, and phase composition analysis to ensure product reliability and consistency.

Is zirconium oxide supplied by Ti Time Company biocompatible?

Yes, our zirconium oxide is biocompatible, making it suitable for dental crowns, bridges, and implants.

Why choose Ti Time Company as your zirconium oxide supplier?

Ti Time Company combines experience, expertise, and trustworthiness, delivering high-performance zirconium oxide with full technical support and global supply capabilities.